How

To Repair

1989 Dodge B250 Ram Van Wagon 3/4-ton 8-cylinder 5.2L 318 in3

© 2010-2020

Brian Mork

Home

•

Site

Index

• Wiki

• Blog

Introduction

This web page contains a narrative log and

pictorial essay to maintain a 1989 Dodge B250 Ram

Van with 5.2L engine

with 153,000+ miles. At the bottom, I also have some simple

graphs aggregating lots of data on costs. This page is meant to

teach you, document technical data, and perhaps most of all motivate

and encourage you as you try to figure out your non-working Doge van.

I

included lots of links to web resources I found

useful. Chad's 1989

1-ton B350 van repair log

is also helpful. I have other pages about my 230,000

mile 1994 Suburu Legacy

with 2.2L. and 100,000 mile 2003

VW Jetta wagon 1.9L diesel. I always appreciate your link back to

this

page so Google

thinks what I say is important!

Before you start work on a car project that may take several weeks, consider

canceling insurance or doing "storage" insurance. My insurer used to

provide a "storage" option that provides only comprehensive

coverage and drops the cost of a newer vehicle from $52.50/mo down to

$5.00/mo. More recently, they've changed the definition of

"storage" to mean "state mandated minimum insurance," and for the Dodge

van in this article that change drops cost from from $27.17/mo

to

$6.70/mo. Or, if you can handle the risk, you could remove ALL coverage

including comprensive and save a boatload of money.

Bad Auto-Shutoff Device (ASD) Relay

Shift Lever

Catalytic Converter

O2 Sensor

Brake Cables

Battery

Brake Hydraulic Lines

Electronic Trailer

Brake Controller

Frame Hitch

Window Regulator

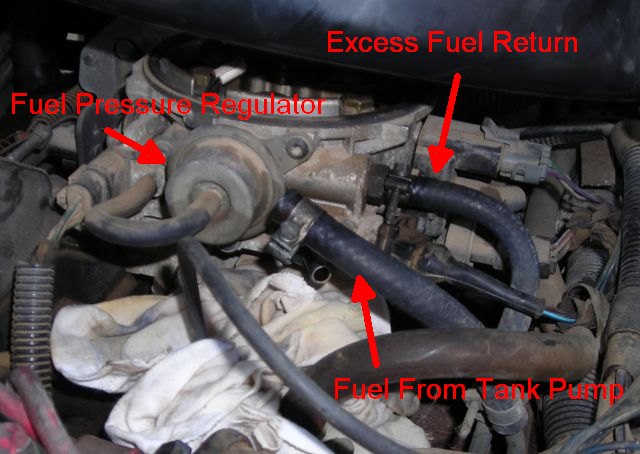

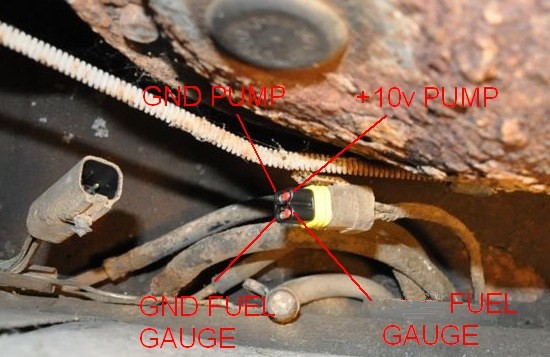

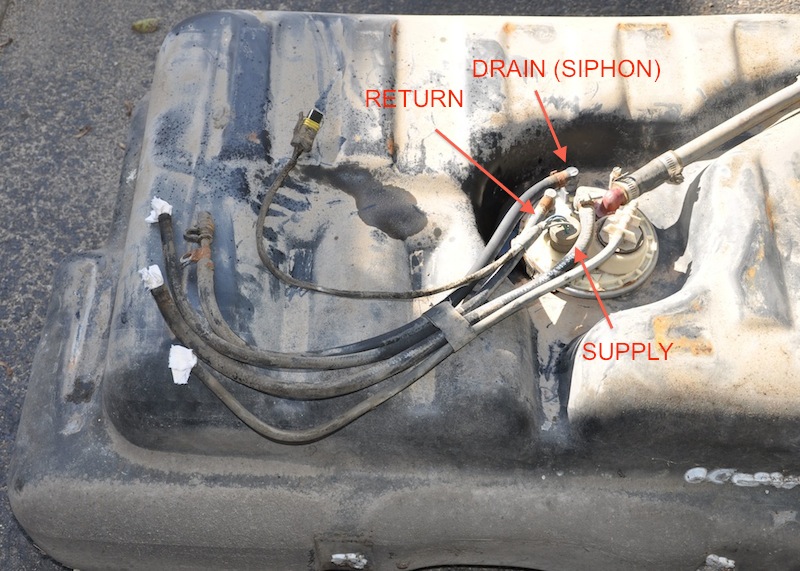

Fuel Pressure

Suspension Bumper

Air Conditioner

Compressor

Testimonies

1/14/2011 RN from Minneapolis,

MN wrote, "Thank You very much for

your informative article on

troubleshooting the Dodge B250 Van. I just experienced the same

situation with mine and thanks to your expertise I was able to do as

little as jiggle the wires around the relays and it started right up.

It was a LIFESAVER!"

1/19/2012 RS from mac.com wrote, "In

reference to your page on Dodge van exhaustive information ....

THANK YOU !!! Fantastic information ... great detail ... so much

appreciate! Very best regards ...."

4/11/2012 SS from Texas wrote, "I am

impressed! Gee, will you marry me!

For the sake of the baby, of course...(smile) Honestly, you

have obviously spent many, many hours on your Dodge van project. Thank

you so much for your time and energy, in both the labor you have spent

on the van, but moreover, the excellent record log you have provided!"

4/1/13 BR from Québec wrote, "The problem you

describe on internet that you finally solved was of great help for

me; I had a similar problem and your explanations solved it.

I talked to a mechanic and there was so many things possibly wrong,

that it would have cost me a fortune to leave it to a garage. I saw

your article on internet and followed what you have done or checked and

my problem is solved. Considering the age of my vehicule, it was a

matter of finding and fixing the problem or scrapping my Dodge

with 'only 122,000 miles' on it. My wife and I love it very

much. You saved our vehicule and our way of life."

11/21/14 RS from mymts.net wrote, "Found

the same thing on a van that was parked outside all summer, went to

move it in and no start. Checked fuses and then checked

internet, viola the relay was replaced prior and was hanging upside

down. Just wanted to say thank you for posting that blog."

8/27/16 NM from Canada wrote, "This

is great...thanks for the info....much better than ___."

12/4/18 AM writes, "...excellent blog and pictures.."

6/11/21 KB writes, "Amazing! Thank you for your hard work and

putting your knowledge out there for other Dodge owners to benefit!"

Spring 2009 - ASD Relay

The

first problem I worked on was doing a repair to the ignition. Early

spring 2009, my

1989 Dodge van with 135,000 miles was working fine, then one Sunday

morning, it sparked a

bit, almost started the engine, and quit. The engine turns over

fine - good and strong electrics, but it won't

produce

any spark, and won't run.

Click

on any picture to see a

close-up view.

Our

van is affectionately known as "Big Blue". It's been across the nation

at least eight times and we hope it has a lot more life in it! Looks pretty nice even in

the cold snow.

We

have loved camping in it so far, and the rear seat comes out

for cargo hauling.

|

Tools are stacked up behind

me for easy access.

|

One convenience of the

full-size

Dodge vans of this era is that the engine is worked on from the inside

of the van. This is particularly nice during Michigan winters

when no

garage is available! Water on the floor is snow melt off my

boots.

|

Ignition

parts up close. The distributor is beige with wires coming

out

the top. The coil is round and lays horizontally to the right. I pulled one of the spark

plugs going to the right in the picture, and could get no

spark.

Finally I pulled the central cable going *into* the

distributor and hooked it to a spark plug.

Nothing. Not good.

|

3/4 view of the ignition

coil and the spark plug I had out and was testing. You can see the

plug I pulled. Actually, it

looked

in pretty good condition. Looks like my valve gasket is

leaking a

bit of oil.

|

Coil and distributor. another

view of the coil assy. See the little grey wire?

There's one on the other side, too. They both

disappear into

the wire bundle, and I don't know where they go. Unscrewing

the

terminals is pretty easy and I did tests with wires removed and in

place.

|

Dropping

a bolt or screw down the throttle throat would be bad! To work on

the twin fuel injector harness, you

have

to remove the air filter and jostle the metal support aside.

|

Inside

the distributor looked really clean for 135,000 miles. Must

not

be original. I picked up a spare spinner and magneto pick up from the

junk yard.

|

With

the distributor cap off, you can see the black disk in the bottom

(magneto pickup), and the spinner that puts spark out to each of the 8

cylinders.

|

Side

view. The distributor body looks a bit corroded, but

everything

inside was nice and clean. A little bit of pitting on the tip

of the spinning conductor.

|

With

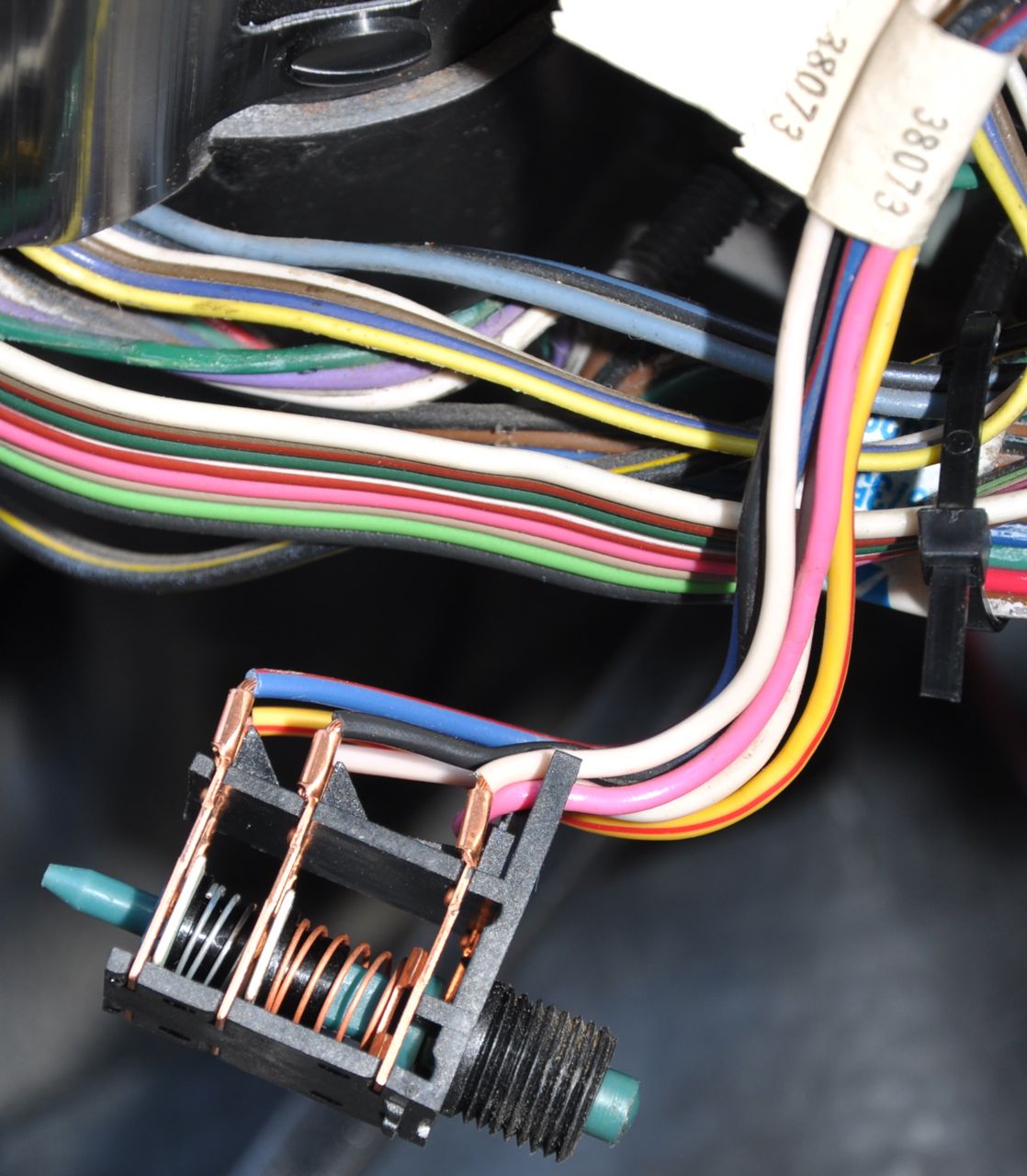

the lower dashboard panel removed, you can see the black box ASD relay

I was working on for 90% of this project. Uh.. turns out that

feeds only the custom interior lighting! It was the WRONG ASD !

|

Having

exhausted every other possible problem, I dug into the "brains".

This the the computer ECU (Engine Control Unit) or PCM

(Powertrain Control Module) or SBEC (Single Board Engine Controller).

|

I

went to the local junk yard and pulled a ECU from a year (1988)

earlier 6-cylinder van. Would it work? I pulled the

air

cooling cover and compared them. Torx driver required to remove the

cover.

|

The

top plate or layer inside the computer is the higher power switching

transformers and voltage controllers (heat sinks) that use the white

connector. Underneath, the fully encased computer circuits

using

the red connector.

|

1989

8-cylinder. If you zoom in close, you can see the individual IC chip

numbers. Hey, I used to use these CPU chips in other projects

computer projects!

|

1988 6-cylinder. Only

significant difference I could see was one less air cover mounting

screw.

|

This

is what turned out to the be the real ASD (mounted on the firewall).

See the little grey box? That's the corroded ASD relay that

someone put into the harness. Water dripped down the harness

and

collected in the relay

|

On the left: culprit and

cause. In the middle:

the interior custom-lighting switch relay found under the dashboard. On

the right:

two relays pulled from a 1989 model van. They seem identical

electrically, but have plastic molding that keys them into one

connector or the other.

|

Original ASD ready to be

connected to the wiring harness. See how the relay body

itself makes a little water-proof hood?

|

The

ECU is connectd with three hex head bolts. Two were badly

corroded. One snapped off when it was removed. I

was going

to drill it out, but managed to untwist it with a pair of vice grips.

|

Original

8-cylinder ECU back into position. The 6-cylinder ECU was in

position when the van came back to life, so I know either can be used.

|

Thursday

(4 days into a repair job):

No

spark. I pulled a spark plug and held it up in the cabin area against

the engine block to see if a spark was visible. Nothing.

Fuses okay. Trying to figure out why there's no spark.

How can I check the coil? Where do the signals come

from

that go into the coil?

Friday

(5 days):

I

opened the distributor (pic r2c3,4,5) and played with the ignition coil

(pic r2c1). In picture r2c1, you can see

the

two terminals, with almost-red copper tips to the little bolt

ends. The two terminals are the primarly, and the large central

wire is the high-voltage output (compared to ground).

When

I removed the upper nut and grey wire, across the coil primaries

measured about 3.9 ohms (later tested to 1.6 ohms with a better meter).

I turned the keys on and the forward

and

lower nut was about 11.7 volts compared to ground.

Later, this was not reproducible and there was no voltage on

the coil anywhere. [later

note - I think the skittish voltage was because the shutoff relay

contacts were intermittent and failing with water corrosion.]

The upper

disconnected terminal was also 11.7 volts through the coil until I

connected the grey wire back on. The grey wire seems to

be holding the whole thing grounded because both terminals

then

moved to about 0 volts.

The

red wire secondary coming out of the coil center seemed loose so I

played with

it. It spun out easily, taking the center stem of the coil

with

it. I disconnected the two and screwed the coil stem

back in

firmly with a phillips screwdriver. While

the wire was off, I measured the wire alone and I think it was about

1.4 Kohm.

I remembered that these wires have built in resistance

to

cut down on ignition noise, so that seemed okay.

Chilton's

books specifies a maximum of 7 Kohm per foot. I clicked it

back

firmly onto the centerstem of the coil.

I

did the spark

plug test again by turning over the engine, and this time

got about 5 sparks,

then intermittent, then it quit doing any sparks while turning

over the engine. I

jostled

the wires around and my hold on the spark plug and tried again.

No

more sparks. Something is marginal, but mostly not working.

The voltage spike coming out

of the ignition coil primary is routed into the distributor, and then

it farms out the voltage to the right cylinder in sequence. After

pulling the distributor top, I couldn't

figure out how to remove the spinning stem from inside

the distributor to look deeper. A friend sent an incidental

description of how the distributor is suppose to work:

"Dwell

time is a term used to describe how long (degrees angle) the

points (mechanical) stayed closed. Mechanical points

stay

closed much of the time (shorted to ground). It is at the

moment

the points OPEN that the Spark actually occurrs. When the

points

OPEN, the field in the coil collapses and causes a high-voltage spark

in the secondary circuit of the coil, many thousands of volts, enough

to cause your spark-plug to spark. So........a coil is

basically

a step-up transformer you could say. The AC type current you

are

apparently seeing at the primary terminal on your coil while the engine

is rolling over is normal and to be expected. Actually, it

should

be AC current in that is vacillates from zero volts to around 12 volts

right? As you said, without an occilloscope, it would be

difficult to actually see this pattern with much accuracy using a

volt-meter.

Dwell time in a computer-controlled system is

greatly enhanced because the dwell can be increased thus providing more

field saturation time in the coil and the subsequent hotter

spark."

Saturday

(6 days):

I

pulled the coil off the engine and started testing things. Across

the

primary tests 1.6 ohms, which matches specs I found at Autozone. I

found 9.6

Kohm

from the secondary to either primary terminal. NAPA had no way

to

test this, but let me check one of their coils. Identical.

I think the coil is okay. I

don't have my oscilloscope out and running, so I can't see exactly

what happens, but the voltage settles into an AC signal across

the

coil primaries, so I think the ignition module is doing

something.

Safety alert! I let

the grounding lug for the coil mount float unconnected

and turned on the ignition. When I did this, the

fuel injectors went full bore ON and

started spraying lots

of

gas down the throttle valves (pic r2c2).

I

couldn't tell what the gushing sound was, and then saw it! Don't

do testing with the ground wire lug of the ignition coil disconnected

or you're sure to

flood the engine or start a fire. This is still a bit

confusing. With the ASD energized, the "Z1" wire should be at 12

volts. Maybe the diagram below is simplified too much and the

ignition coil provides a DC ground keeps the fule injectors off, and

then I let it float up to the 12 volts?

Autozone

was willing to test the ignition module transistor, but I can't find it

yet. I've looked all over on the firewall. It's just

not

that complicated, and I can't find it. There is a

big bundle

of wires going into a plastic shroud covered item about 6-8

inches

across about in horizontal center of the firewall. I think

it's

the computer module. I'm fearful that the

ignition module

is buried in the bundle somewhere, or part of the computer module.

[later note - yup, the transistor is

in the ignition moduel on this van; that's why I couldn't find it.]

I read

on on the

internet, a post about control modules from years prior:

"I

have the same year and make of pickup [truck]. The problem is

in 1988 depending

on how early or how late in the year it was produced it could have 2

different ignition systems. If its a late model like mine it

wont

have an ignition module. Late models ran a hall effects pick

up in

the distributor. Which just relays a signal to the computer

and

tells it when to ground the coil to send spark to the

distributor. But on the early models it should be on the fire wall or

the drivers

side fender well. good luck hope this helps you."

This matches my observation in

my 1989 model that there is no separate ignition transistor

module. It's embedded in the computer module.

Monday

(1 week 1 day):

I found out how

to do Chevrolet

1980s-1990s computer service codes (more authoritatively

listed on the Mopar computer spec sheet, linked below).

Basically,

within 5 seconds, turn the ignition power on-off-on-off-on, and then

wait and count blinks. I was getting codes 12, 42, and 55.

12 is a generic "battery has been disconnected" code that

seems to always show up. 55 is a "end of message" code.

42 is meaningful, and can have several similar

interpretations as listed on Alpar's web page and the Chilton manual:

-

42 Automatic shutdown relay circuit open or shorted, OR

-

42 Fuel pump relay control circuit, OR

-

42 Z1 voltage missing when autoshutdown circuit

energized

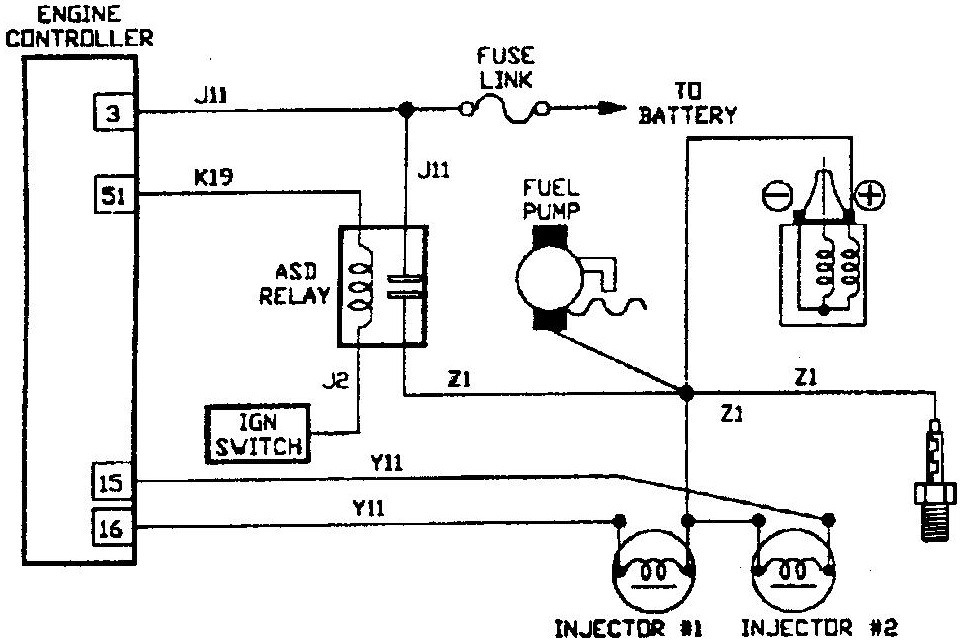

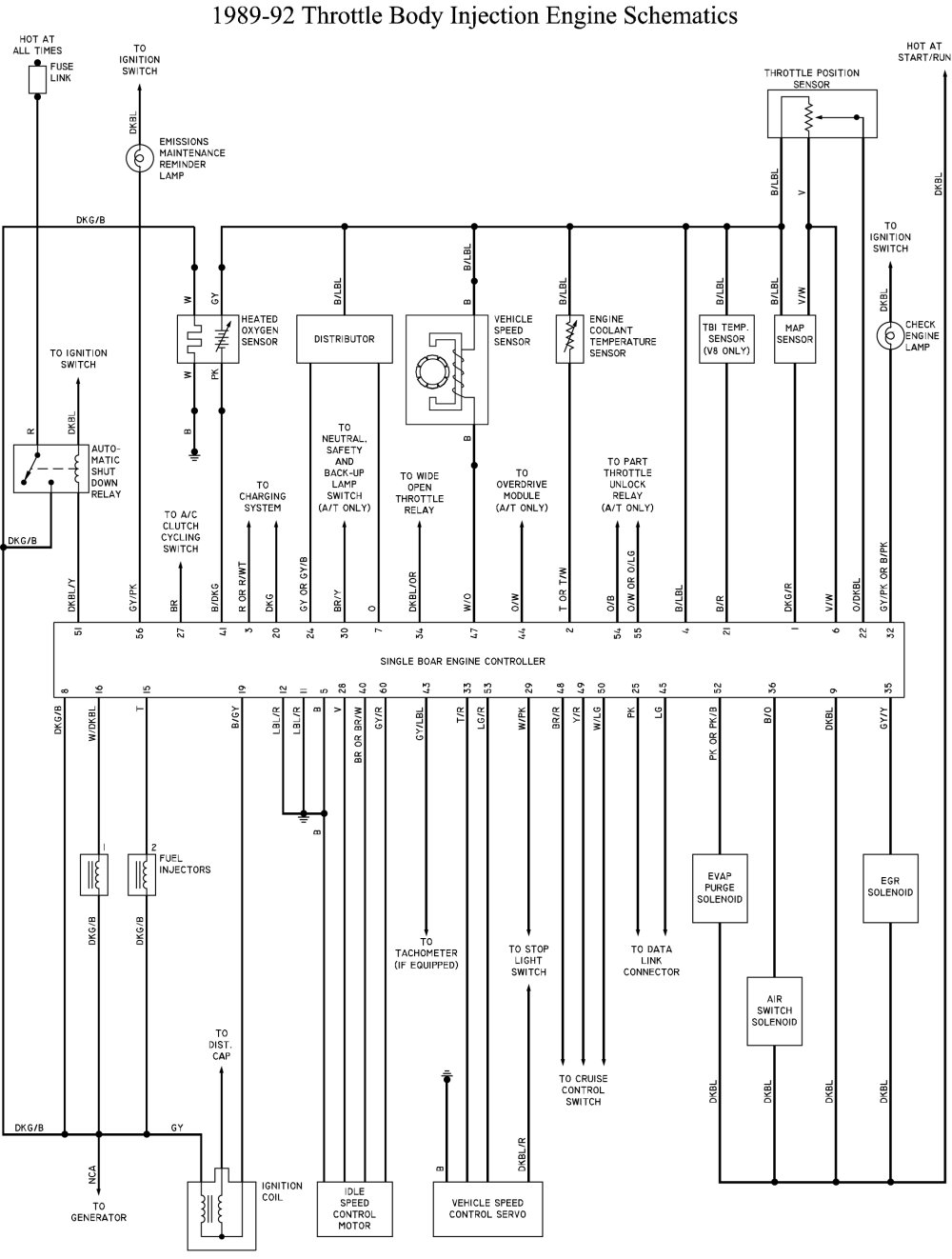

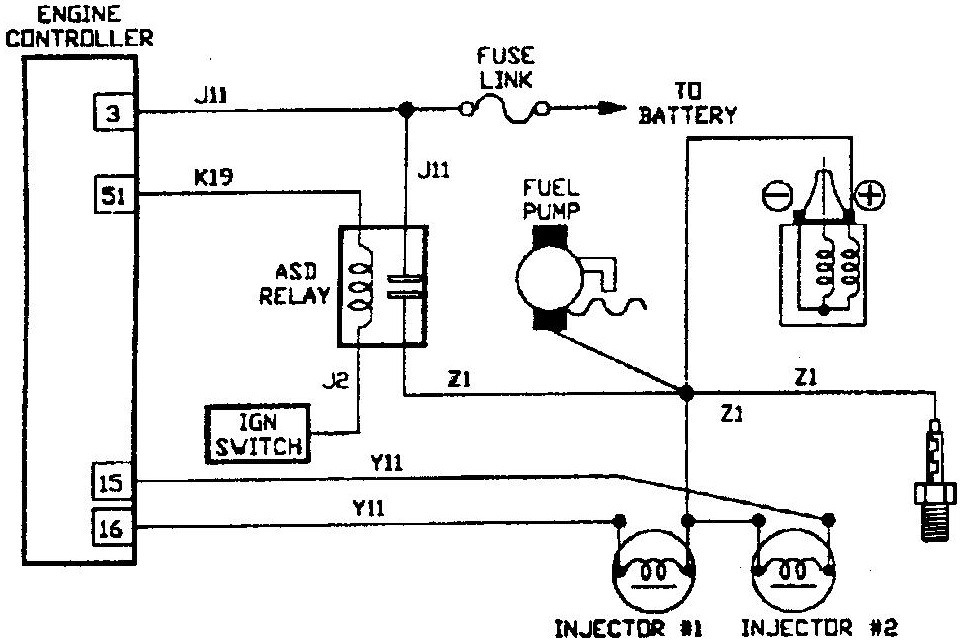

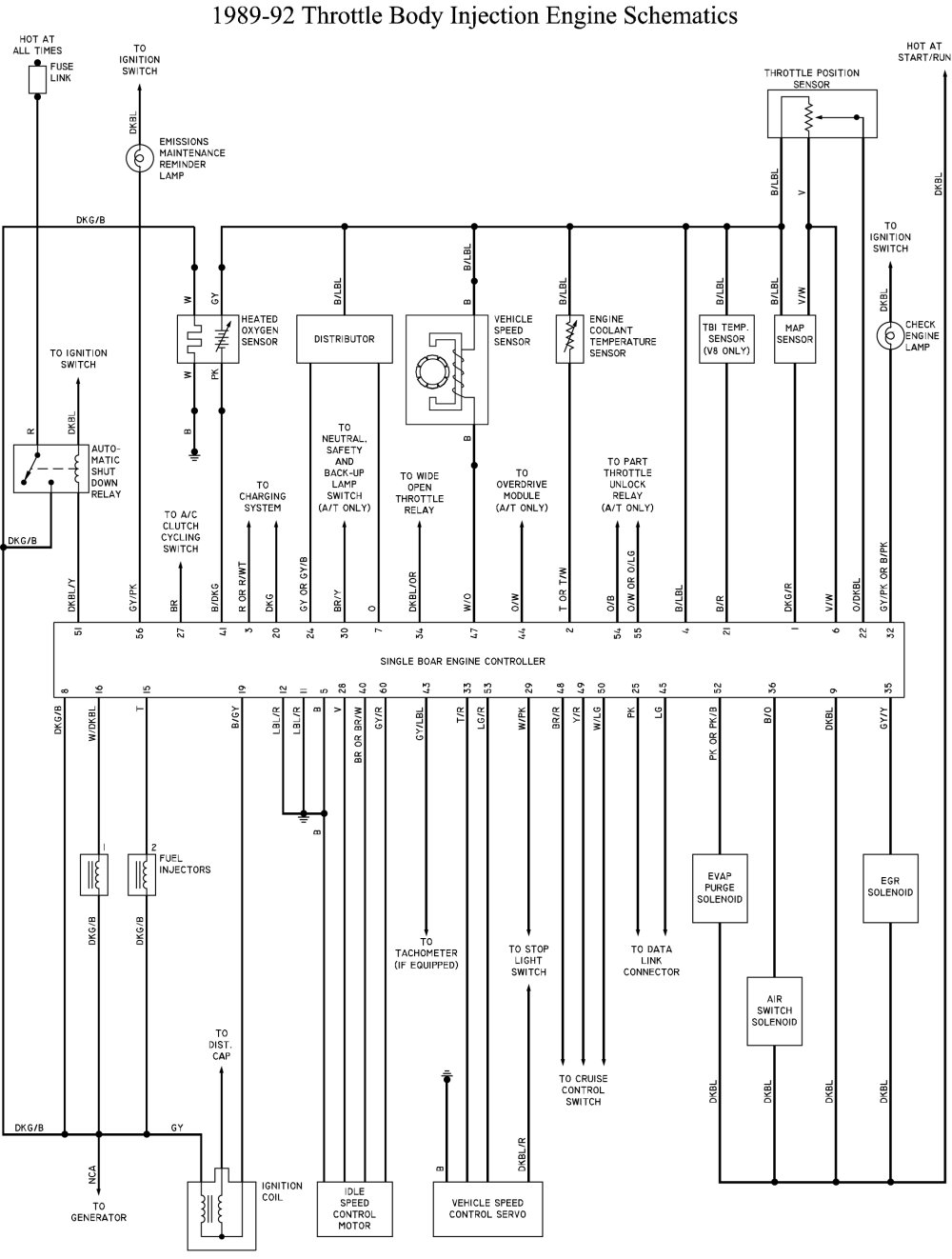

The Z1 voltage is the voltage of the circuits fed by the

autoshutdown relay, shown in the Chilton's

schematic diagram. This

includes fuel pump and

switched-battery feed to the ignition coil(s). The Z1

circuit leaves the Auto Shutdown Relay and splits into two paths: the

fuel

pump and the positive side of the ignition coil. The ASD relay (and,

therefore,

the Z1 circuit) also feeds the fuel injector(s) driver(s).

I don't

think I have any trouble with the fuel pump.

In fact, as mentioned above, the fuel sprayed out under pressure

when I disconnected the

high-voltage spark coil from grounding mount screw.

To check

these codes, I

unconnected the negative battery terminal while charging the

battery from another car. I unscrewed the computer covers and

took some pictures for about 1/2 hour and then hooked up the negative

side

cable and read the codes without trying to start first. I

received 12 and 55 (no 42). Then I tried to start and it

happily cranked over and over with plenty of power, but did not fire

once. Checking codes, I am now again receiving code 42.

The local

Chevrolet dealer

says they have no more 1989 manuals, and so

he can't advise where the ASD relay is at. He said it should

be stamped with the number "52-33-302" and costs about $28 to buy a new

one. I found two relay-box looking things bolted to the

firewall.

One to the immediate side of the main computer box toward the

driver side. The second is down by the driver's right foot.

One has an obviously different number; the second has no

discernable number. [later note - the

one on the firewall by the driver's foot was the ASD relay, but I

didn't recognize it at the time.]

Tuesday

(1 week 2 days):

I

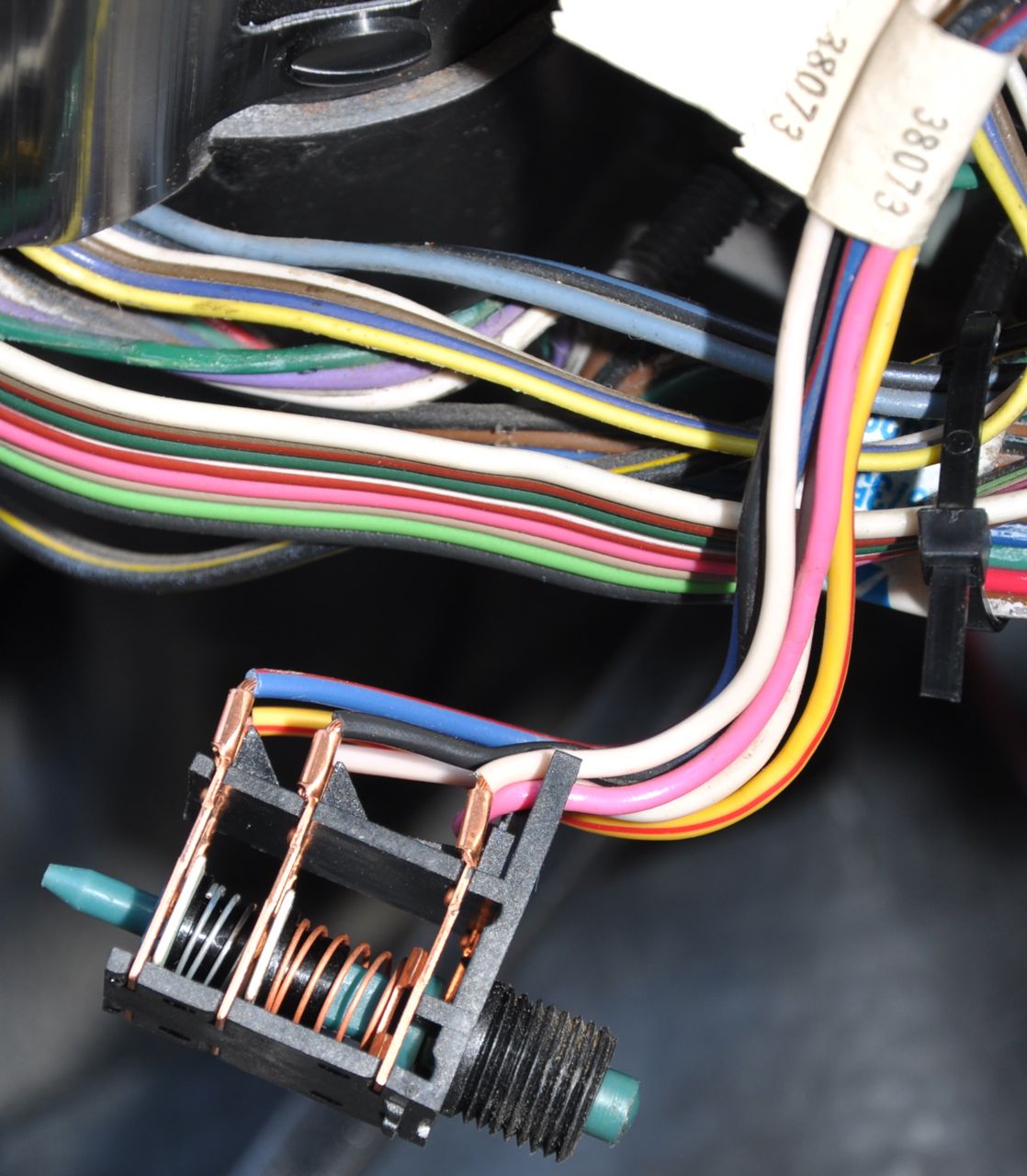

found the ASD Relay. It's a black box in the wire bundle up

under

the dash, outboard side of driver's left leg. [Caution

- read

this entire article! I initially found an ASD relay that had been wired

inside the cabin for the custom interior lights. It has nothing

to do with the

ignition, which is why I started getting unexplainable behavior

thinking it was the ignition ASD relay.]

Mine

has a part

stamped "46385" and inked "4273307 0179". Lots of electrical

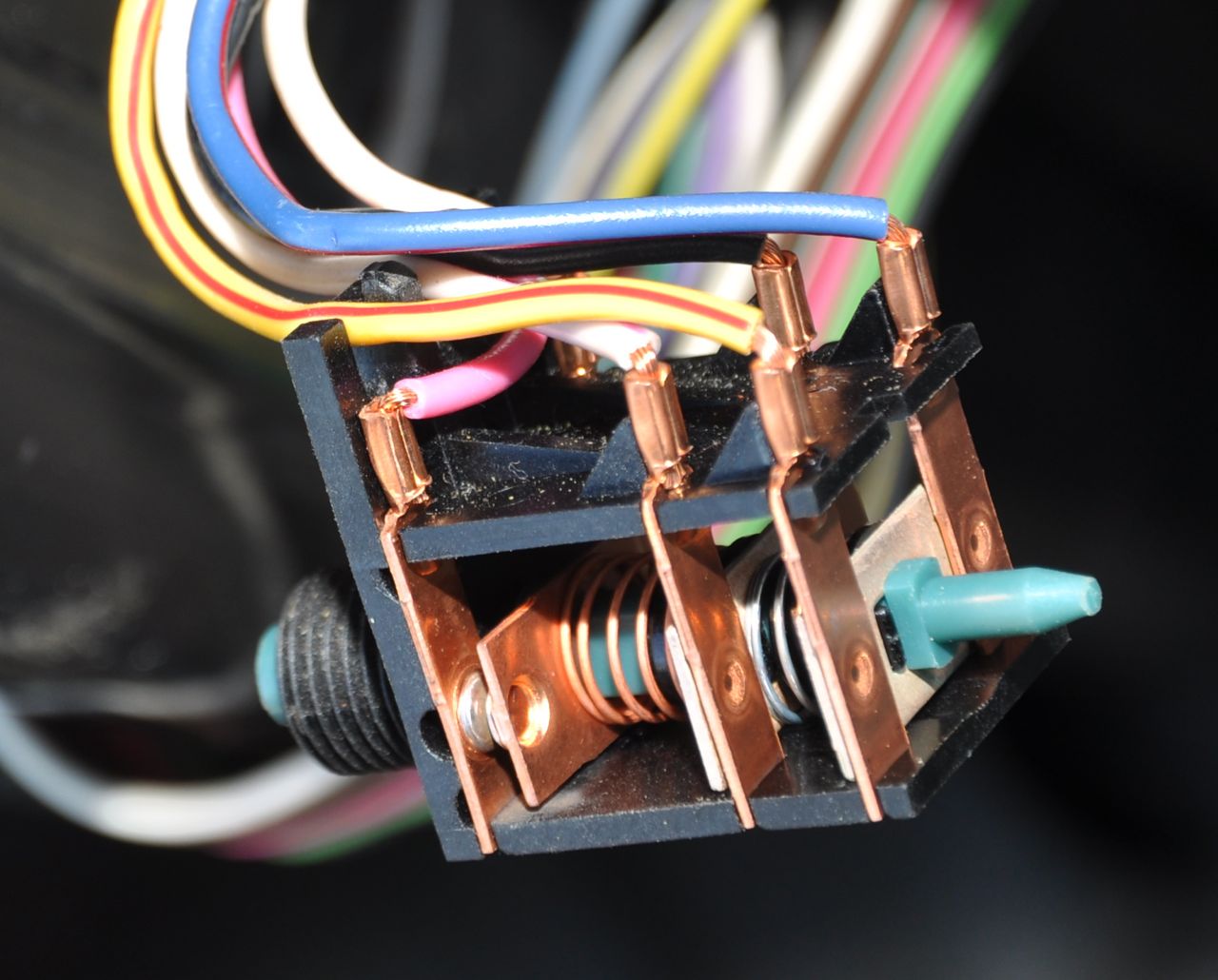

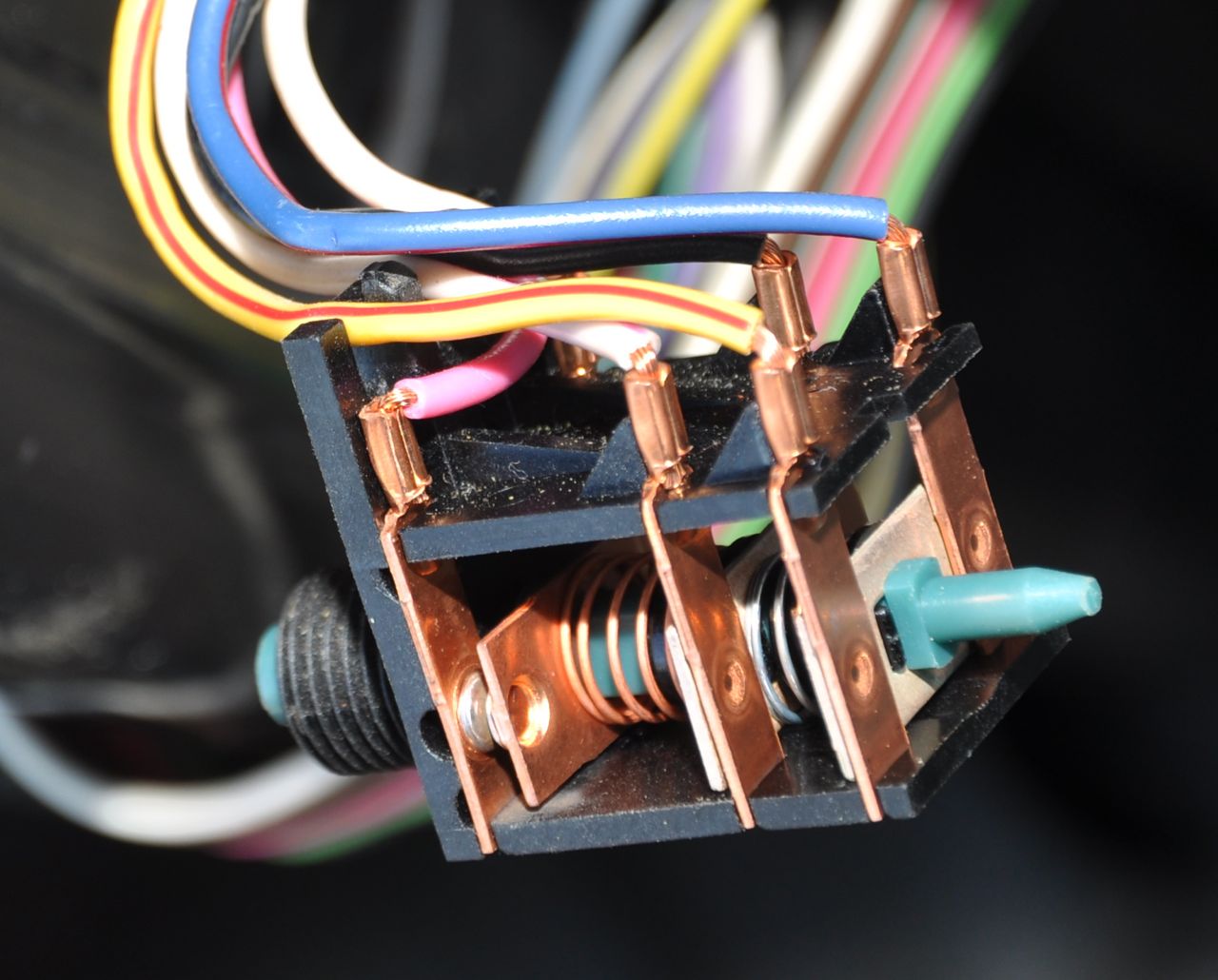

testing today. I found an ASD

relay electrical mechanical pinout diagram

at dodgeram.org. Basically apply 12 volts across the side

terminals activates the relay, and the up/down terminals are the

contacts. Normally-Open on the

top. Normally-Closed on the middle. Common on the bottom.

The four terminals are

numbered 30, 85, 86,

and

87. Looking at the male pins of the relay, pin 30 is on the

bottom and pin 87 is on the top. Pin 85 is on the right, and

86

on the left. Looking at the female connector for the relay,

pin

30 is on the bottom, and pin 87 is on the top. Pin 85 is on

the

left and pin 86 is ont he right. A textual

description of ASD relay pinout is available at

justanswers.com. I posting by "dsramprat" at

automotiveforums.com gives a checkout

procedure for the ASD relay.

- Pin

30 - pink/red wire - bottom of relay receptacle or cavity. Car always

provides

+12v even when there's no key in the car. This is confirmed

to be

connected on the rear or bottom side of Fuse 6 in the glove compartment

(0.7 ohms with fuse removed). It also goes to Pin 3 of the

ECU

according to Chilton's. This voltage drops to about 9.75 v when

cranking the engine ... yea my battery is getting weak after all this

testing.

- Pin 87A - middle pin on my relay is clipped

off,

the outer

pin is intact.

- Pin

87 - brown wire - top of the relay cavity connectory. This

is the relay output. Power from Pin 30 is switched to this

pin

when the relay is energized. Feeds the "Z1" circuit that

includes

fuel injectors, ignition coil, and probably oxygen sensor heaters, and

generator (alternator) field.

- Pin

86 -

white wire - +12 v from the car when the ignition switch is on.

Other

sources

indicate it is fed through Fuse 9, but that appears to be not true with

my vehicle.

- Pin

85 - black - I believe the ECU grounds this in order to switch the ASD

relay on, probably by pulling the collector of a transistor toward

ground. Resistance between pins 85 and 86 is about 82 ohms,

implying 12/82 or abou 146 milliamps draw when powered. That

would not be too much for a transistor.

Okay..

that's all great. Relay appears to work out of the van.

In the van, things get wierd. [later

note - Remember, this was the incorrect interior ASD relay that I

found; I was basically testing the interior custom lighting circuits,

which is irrelevant and confusing.]

White

wire ignition +v on the hot side of the relay coil stays at constant

+12v when

ignition is on and not cranking the engine. It drops to about

1v

within a second when cranking, and then returns to 12v as soon as

cranking stops. Chilton claims this is direct from the battery through

a fuse link. Another web page says fuse 9, but that did not

check

out on my van.

Brown

wire relay output goes to +12v when the ignition is turned on.

It drops to 0 v when cranking and returns to 12v when

cranking

stops. This is true with or without the (-) side of the

ignition

coil connected. This is an important distinction because

theoretically 12v / 1.6 ohms or 7.5 amps of current goes through the

coil, and this could draw down a voltage.

Resistance

checks indicate the (+) side of the coil does not appear to be

connected to the brown wire pin 87 ASD relay output as shown in

Chiltons. So I'm not sure the simple circuit diagram is

complete. [later note - I was testing the wrong relay; the output was

literally connected to nothing]

The

hot side of the coil primary behaves differently, too. With

the

negative side disconnected (no load), it sits at 12v with the ignition

on, and drops to about 4v when cranking. Remember, this is

without current flowing through the coil. With the (-) side of the coil

connected, the hot side is never above 1 volt DC. I don't

have an

oscilloscope to watch the fast time behavior, so it might be pulsing up

to 12v as it should, but I can't be sure.

When the

coil hot

side is at 12v, the relay output is also at 12v. In order to

be

sure I wasn't reversing the relay connectors, I floated the entire

meter and just monitored voltage across the relay coil (pins 85 to 86).

It was 12v when the ignition was on, and dropped to 0v within

a

second of cranking the engine. Based on this, the relay is initially

energized, and then is NOT energized as soon as cranking starts.

Output voltage is 12v when the ignition is on, and

drops to 0v within a second of

cranking the engine.

Wednesday

(1 week 3 days):

With

the relay hooked up in place in the van, I hooked up 4 jumper cables to

monitor voltages [later note -

remember, this entire day of testing was with the wrong relay].

The relay coil measures 80-65 ohms,

depending

on how long I let the voltage die away after having the ignition on.

It stabilizes long term at about 65 ohms, which is okay since

there are other circuits in parallel.

Relay

primary

With

the voltmeter floated across the relay coil primary circuit, it is

13.7v with ignition on (coil is energized). When cranking, it drops to

about 0 volts across the coil, and rebounds to 13.4 v after cranking. I

can also feel the relay click on, with ignition, then off when

cranking, and on again when cranking stops.

Interpretation -

during cranking, the ECU releases the grounding on Pin 85 allowing both

sides to rise up to +V, or the ignition +V drops down to ~0 v to match

what the ECU is commanding. Is

ECU releasing, or switched

ignition +V is dropping? [later

note - actually, the pin

86 +v ignition voltage was dropping away because the *real* ASD relay

was being turned off by the computer almost as soon as it turned on -

which is what it's suppose to do whenever the computer sensed the

crankshaft of the engine was not rotating]

Relay

contacts

The

hot side of the relay contacts stays at permanent +V no matter if the

key is in the car, or ignition is on, or off, or if cranking or not. Connecting

the voltmeter across the relay contacts, shows that the voltage across

the relay always hovers about 0 volts, bouncing around a little bit.

That's strange since I would expect the output to not hang around +V

when the relay is open.

Output of relay contact

compared

to ground is ~ 0v when the car is off, +V when the ignition is on

(should be since relay is closed), and t hen ~0 v when cranking.

Strangley, across

the relay contacts always hover about 0 volts, cranking or not.

Since

Pin 30 is confirmed fuse 6 +V, this means the output side of the relay

must float up to about +V even when the relay is not closed. [later note - the output

was a

floating wire connected to nothing; voltage reading was meaningless and

I should have noticed that by the floating around behavior.

Using an

oscilloscope would have shown random voltages on the unconnected wire.]

Checking

the relay out of the car, with the car battery across the coil, gives a

solid click and release. Resistance goes from infinite down

to

less than an ohm. Interpretation? Relay is fine.

Summarizing

three states:

- Power

off the van - Supply side of contact (pin 30)

is at +V.

- Ignition

on - Coil hot side pin 86 is at +V, ECU is grounding pin 85,

energizing the relay. Supply side of contact is at +V, and

relay

output pin 87 is +V.

- Cranking

- 0 volts across relay coil, indicating relay is commanded

de-energized. No voltage output at pin 87 output but it also

seems to float up to +V when a floating measurement is made; this is

true even with fuel injectors and ignition coil disconnected (no load).

Also output shows no AC signal, and no conductivity to ground

with power off.

|

power off |

ignition on |

cranking |

Description |

pin 86 relaly coil -

ignition

+V power available

|

0 |

12v |

1v |

This is capable

of sparking and heating small jumper cables - be careful what you let

this touch, especially pin 85! |

| pin 85 relay coil - ECU

grounding relay energize |

not measured |

not measured |

not measured |

I don't know,

but I'm betting there is a transistor inside the ECU with a transistor

collector terminal pulling this to ground when appropriate. |

| across 85-86

coil |

0 |

13.5 v |

0 v. |

ECU commands

relay closed with ignition. Commands open when cranking. |

| pin 30 contacts

input |

12v |

12 v |

10 v. |

Slight loading,

but otherwise stable power. |

pin 87 contacts

output (suppose to be switched 12 v)

|

0 |

12 v |

~0 |

Feeds

downstream circuits with +12v power when the ignition is turned on. |

| across 30-87 |

0 |

~0 |

~0 |

Consistently measured ~0

volts [later found output wire was floating unconnected to anything] |

Other

observations. Maybe a tan wire from pin 87 output goes to fuel

injector? Checked with ohmeter. No. Fuel

injectors

have about 3 ohm across coil. Top two pins and bottom two

pins of

4-pin connector.

Why does ECU command ASD relay open when

cranking? OR, why does switched ignition power die?

Is this

about the crank case indicator not giving a pulse when trying to start?

Chilton manual shows crank reference signal error diagnostic

codes for years 1996-1998, but nothing for 1993-1995 vans, and nothing

about crank signal for 1989-1992 vans (mine).

Check this and confirm crank sensor is giving a good signal.

Otherwise ECU cuts out the ASD relay.

Saturday

(1 week 6 days):

Salvage

yard shopping trip with a friend (thanks Kevin!). I came home

with replacement computer,

replacement

distributor wires, replacement oxygen sensor, replacement

fuel injectors. I should have grabbed the coil, too. In

case your local salvage yard does not have the appropriate vehicle, you

can also purchase new SMEC computers

from Mopar.

Looks like my 8-cylinder 5.2L 3-speed vehicle uses part R4379887,

4-speed uses R4379889 for FEDeral state-side vans. (Okay, side

question: If I have 3 spd plus and O/D overdrive switch, does

that mean mine is a 4-speed?) The one I actually found at the

junk yard came from a 1988. I'm not an engine expert, but

considering it had a 6-cylinder, it must have been a 3.9L LA V6.

That would be SMEC or SBEC part R4379929 for FEDeral or CANadian

vehicles. Direct replacements are available on the web from autopartswarehouse.com

or other distributors for about $170.

Sunday

(2 weeks):

Replacement

computer didn't change anything. Relay output still stays

high

with ignition, drops low during cranking. Error code 42.

Monday

(2 weeks 1 day):

ASD

relay under the dash still works fine. Actually, I found

another

relay forward of the firewall on the end of a dangling wire bundle that

has the same electrical connection

with the middle pin 87A (NC Normally Open) tab in place. Not

sure what this relay is for, but regardless of the part number, it

looks like it could be used for an ASD relay. [later note - boy was I dense! My

brain still didn't recognize this as the real ASD ignition relay!]

Is there a ballast resistor circuit that needs attention?

Actually, it would be the parallel

circuit that needs attention. The ballast resistor circuit is

used when the car is not cranking. It provides power to (or

indirectly to) the ignition coil. This is to limit the

current

flow so the ignition coil doesn't burn up. However, when

cranking, the starter pulls the battery so low, that the ignition coil

needs direct power on the (+) side. If the parallel non-ballast

resistor circuit is open, then I would get the behavior I am

experiencing.

Rooting around, I see two wires on the starter,

one big and one little. Follow them up, and I find the little

one

is a brown wire that goes to a connector, joined with a little red wire

direct from the battery. Other side of the connector is a brown and

pink wire, just like the the two colors on the ASD relay.

Maybe?

No... no continuity.

However, I did find two wires

under the dashboard labeled "ignition +v" and "battery +v" with single

wire connectors.

Looks like you can plug one or the other into the red wire

(and

20 A in-line fuse). Turns out this is what feeds all the

interior

lights for the custom van. At least I've learned something

today!

The

brown and pink wire disappear into a wiring bundle, and from there I

have no clue where they go. How exactly does one "trace the

circuit" without knowledge of where it's suppose to go?

I need a working van to start making comparisons to. Or, I'm

about ready to assume

it's a fault on the ignition of the ASD relay that is dropping the ASD

relay, and hotwire

+12v onto the Z1

circuit relay output and hope that nothing blows up.

At

this point, thank you to

friend Neil who sent an email summarizing with essentially this

thought: "When it really starts looking complicated, it's amazing how

often it really is a simple thing that has been overlooked." How Prophetic.

I couldn't sit still and do computer work. I went outside and

after confirming things were still responding as previously, I turned

on the ignition. ASD relay output was +12v. Then I

cranked the engine and ASD relay output dropped to no voltage. Then I

did something differently, while monitoring the current flow with a 10

AMP meter, I

hooked a jumper wire across the relay so that it didn't matter what the

relay was doing. I decided to force +12v onto the Z1

circuitry while cranking the engine. Initially a

quick tap to see if there would be a spark. Nothing.

Longer, and feel for heat in the jumper wire.

Nothing. Nothing on the meter.

No change. No current draw. Switched down

to a 300 milliamp fused scale on my meter. Still nothing!

There was NOTHING taking current through the relay.

This confused me enough that suddenly

realized I had never determined

where the relay output went to. I needed to know. Because if

it fed the ignition coil, there is NO REASON for the ignition coil to

be at zero volts if I was shorting +12v to it. Instead, if

there was a short or something, then the whole ignition coil should

have burned up. Something wasn't right.

Short story? After tearing into the dash, I found the ASD

relay I found fed the wire labeled "ignition +v" wire I had found

earlier in the day. Since my custom interior lights were

hooked to another "battery +v" line (so I can run lights while camping

with

the engine off), there was literally nothing hooked to the output of

the relay. Uhh... very clearly, the ASD relay I had found and

been diddling with for a week was not the ASD relay and it's output

wasn't even being used!

Now that I knew what an ASD relay looked at, I went back with vengeance

to find it. Turns out tucked up next to the brake system on

the firewall, there was a little box hooked to nothing, hanging on a

metal bracket. Dangling near the bracket was a terminated

wire bundle, but when I looked closely, it was not terminated with tape

and a plastic plug like other terminate wire bundles. There

was a little plastic box connected to it. I unplugged in and

VIOLA!! the plugs looked and were labelled exactly like an

ASD relay.

I poked and prodded with my ohmeter and found that this was a

relay, and it clicked fine with voltage on it, but the normally open

contacts dropped to only about 4 Mohm resistance when closed.

The connector look copper blue and corroded. I

think dangling down in the engine compartment made this a perfect water

run-off connection and water got inside the relay and corroded the

contacts.

I took the inside ASD relay from the interior light circuitry and

jumper cabled it into position because it physically would not fit onto

the cable connector. Measured volts and everything looked

good. I cranked the engine, and within 1.5 seconds, the old

Chevy 318 came to life! Boy was it good to watch the fuel

injectors popping fuel into the throttle body. It was still

running on the junk-yard 6-cylinder computer.

I ran to the junk yard with my toolkit and pulled two ASD relays from

a similar van - a 1990 Dodge full-size van with the

same engine. I

also grabbed two headlights. From the 1988 Doge Ram

Van with the smaller 3.9 L engine mentioned earlier, I took a few spark plug wires, and

the ignition coil. $10. I almost got the air

conditioning compressor out to replace my broken one but one bolt was

rusted up badly. I need my long arm socket. I guess

that's for another day...

Tuesday

(2 weeks 1 day):

Now that my eyes

were

familar with what to look for, one of the little boxes bolted

to the firewall

started looking like a relay. And... the wiring harness I

found would perfectly reach it. I unbolted the firewall

device, and looking at the bottom.. sure enough it was an ASD relay. I tested it with

my meters and it behaved perfectly.

Instead of using one of my new relays, I plugged the wiring harness

into the relay that had been bolted unused to the firewall the entire

time. Result? The van ran beatifully!

I pulled out the 6-cylinder 1988 ECU and repaired the one stripped

mounting bolt hole. I put my original ECU back into the van.

I taped up wiring bundles, tucking some behind the battery away from

water dripping, and plugged the ASD harness into the firewall mounted

ASD relay that had been there all along.

Summary? Someone had unconnected the harness from the factory

ASD, plugged in another one, and let it dangle in the water.

I have no idea why

someone

would have plugged a dangling ASD relay into the wire bundle harness

and left a

perfectly good relay bolted in position to the firewall. I fixed the van by plugging the

harness back into the factory

mounted relay and discarding the water damaged relay. What a trip to

get to this simple answer!

Epilogue:

Hopefully our "Big Blue"

van has a few more trips in him. We're anxious to spend a

night out at the soaring club field now that Spring is coming

on. I

now have a small plastic storage bin under the back seat.

Spare injectors. Spare fuses. Spare coil. Spare

relays. I should go pull the distributor sensing coil from the

salvage yard van, maybe

the entire distributor stem going into the engine.

May 2009 - Shift Lever:

Three months later, and several

thousand miles later, the van unexpectedly won't start again!

This time, it wouldn't turn over even though all electrics look

strong. Again my friend Neil's words echoed in my head, ""When it really starts looking

complicated, it's amazing how

often it really is a simple thing that has been overlooked." Uh... yea.. check that the shift

lever is settled

into the Park

detent! On an older van, after the cables have stretched, this

may not perfectly match the dashboard indication. With the

transmission secured into Park, the van started with no problem.

Everything is not a difficult problem. It's okay to look for the

simple, first.

May 2010:

Fifteen months after the starter relay fix, Big Blue

successfully made another cross-the-nation road trip. Working

fine. No other repairs yet. ...still ticking after 22 years.

October 2010:

One more round trip across the

nation, for a total of 5 one-way trips so far. Keeps on ticking!

June 2011 - Catalytic Converter:

Stuck in the office too much,

and not enjoying the outdoors enough, and doing huge job commute

distances, I haven't driven the van for a

while. I took it out to drive it around the block. It was

hesitating and had no power, even under no load.

Pressing the gas

pedal all the way down accomplished almost nothing. The catalytic

convertor was making strange rattling noises, and in fact, the van was

behaving as if a potato was in the tail pipe. Took it to have the

catalytic converter replaced, and yes.. it was all destroyed

inside. $198.75

including parts and labor.

But the lack of acceleration is still there. Looks like more

work. Timing chain slipped? Distributor shaft is loose in it's

bushing? Timing adjustment (distributor body) came loose? It runs

fine to start and idle, so I don't think it's a timing issue. Weak

spark so that it can't do high RPMs?

Research about loss of power and no acceleration on the web at about.com.

No fix immediately apparent.

November 2011 - O2 Sensor:

I was pre-occupied most of the

summer with some contract work requiring a l-o-n-g commute. I

didn't have a chance to test the van more until now. I pulled

computer codes and it reported an O2 sensor stuck at full

rich.

After about 2 hours mucking around trying to get the sensor out from

it's rusty threads, I decided to give up, and took the van to the

commerical repair shop to replace the sensor. Or so, I thought...

They rang up a day later and

reported that the van needed $1600.00

repairs. Uh.. this I needed to see. A visit to the shop the

next morning whittled down the work to about 1/3 of that. After it was

repaired, I received Big Blue back from the repair

shop. It had been

showing zero to no acceleration, chugging, pausing, no power, every

time I pulled away from a stop sign. All I could tell was the

computer was complaining about an O2 sensor stuck on

full-rich.

What came of the visit?

New front shocks. New

passenger-side exhaust manifold.

New valve cover gaskets. Not

exactly

related to the original problem, but the original problem became CND

(Could Not

Duplicate) at their shop, so they couldn't do much with it. Price tag

for the named repairs was $511 plus $78 mail order for the new exhaust

manifold. Big Blue balked and choked and

stalled twice on the way home, but that was during a wet and rainy

morning. For several days afterwards, the van has run well.

However, all the dashboard vents would no longer blow air out. It

wasn't this way when it went into the shop. See the narrative

underneath the first picture to understand what happened.

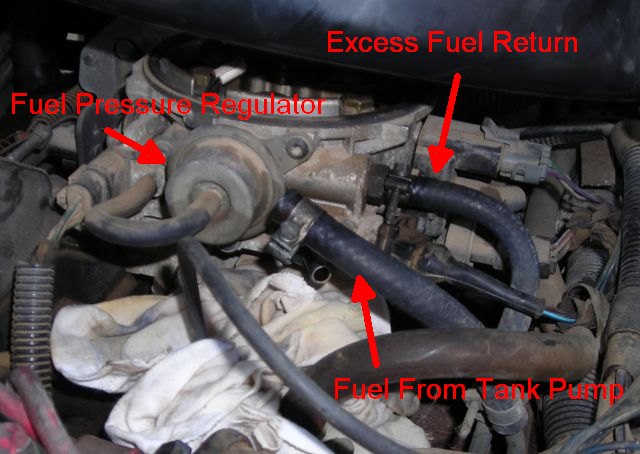

Viewed

from the passenger seat, this is the vacuum adapter mounted into the

intake manifold. It has several hoses connected. The little

vacuum hose hooked on the left side was unbelievably slid over one of

the spring clamp arms rather than the vacuum connector! I

corrected this and now the dashboard vents work again.

|

This

is the vacuum distribution center. Electrical control comes in

from the top left of each switch. Vacuum lines come out the

bottom and go various places.

|

Picture

of the new exhaust manifold. The old one had a rare perfectly

working riser valve (chokes off exhaust if the engine isn't warm which

worked like a spring bi-metal thermometer). The new manifold has

a

port plug where the riser used to be. Two aft bolts were missing

for the last 20,000 miles, and it was time to fix the problem.

Expensive 2.8 hours of labor to drill out most of the bolts, which were

rusted and snapped.

|

Heat

and A/C vacuum lines. The top one comes from the vacuum adapter

on the intake manifold (first picture). Based on what you select

with the control, vacuum is routed out one of the other tubes.

|

Example vacuum

control, visible top center underneath the open hood. This is

with the A/C selected ON.

|

Example vacuum control, visible at

the top

center underneath the hood. This is with the A/C selected

OFF.

|

Another picture of the vaccum

distribution center, back passenger side of the engine. Not sure why I

took two pictures of this.

|

Looking

into the engine compartment on the driver side, you can see the

stainless steel line coming up from the catalytic converter.

|

Oil

was still oozing out of the driver side valve cover gasket and caused

asphixiating smoke when it dripped onto the hot exhaust manifold.

This picture is from under the car, looking up to see the bottom of the

manifold where the oil collected.

|

New blue shock on the driver side,

looking from behind.

|

Passenger side front suspension,

looking from underneath the van.

|

New

catalytic converter. The other one had ceramic honeycomb broken

and shattered into dozens of pieces. Notice the tube coming off the

side, which is routed up into the vacuum system.

|

Driver

controls for environmental controls. The little vacuum lines come

in and connect on the bottom back left side of this picture.

Photography flash was not positioned right, so you can't really see

them, but that's where they're at!

|

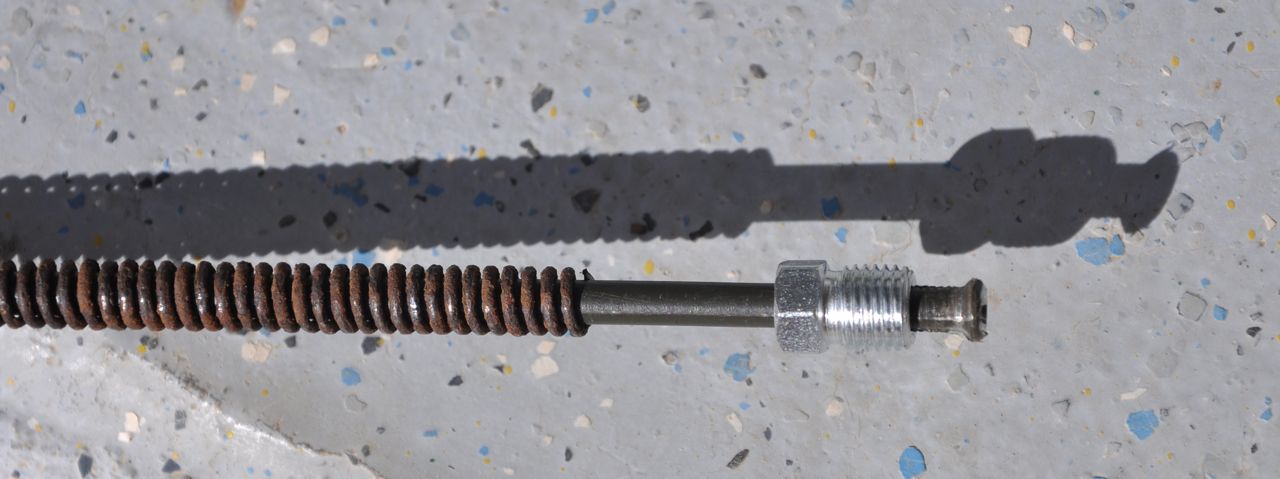

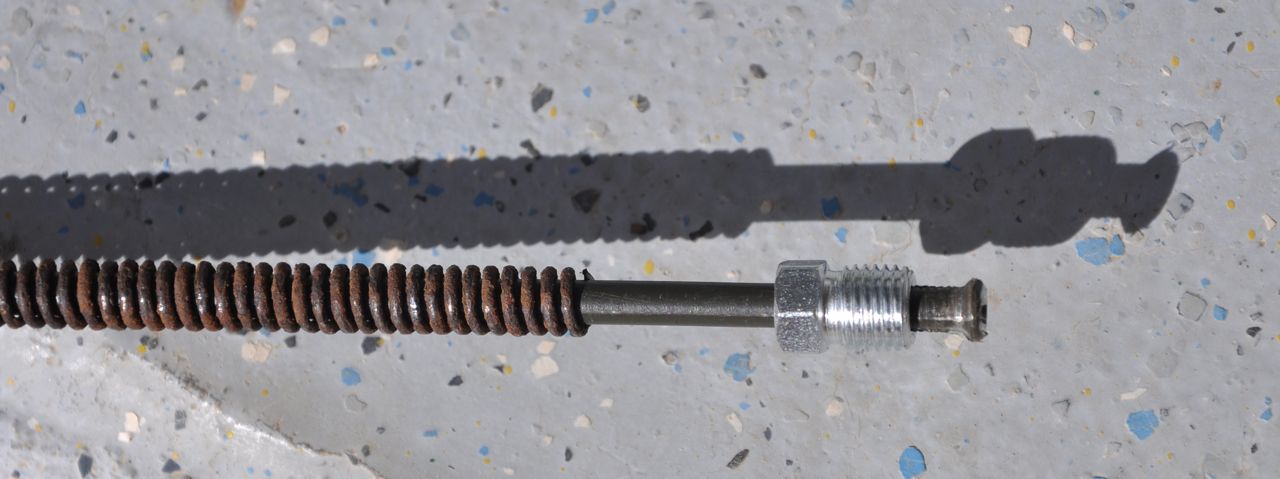

August 2012 - Brake Cables:

The van is running fine, but

with a planned trip to the moutains, it was time to replace the rusted

tight rear brake cables.

I purchased to new rear

cables

from Rock Auto. Price to

have both cables delivered was just under $20.

The

old left rear brake cable had 43" from crimp to crimp. The new

one came in a bit long, and I suspect it's 44-1/8" long. The new

left brake cable is on the right side of this rearward looking picture. |

Closeup

of where the front parking brake cable (top of picture) connects to the

two rear brake drum cables. Notice the clips to hold the cable

sheathing in place are not yet in place (between the rubber sheaths and

the metal mount flange). |

You can see the right rear

cable

extend over the exhaust pip and over the drive axle. The bolt |

Removing the old cables had only one significant problem. The

end of the cable from the front of the van terminates in a long

threaded bolt with an adjustable nut. That nut was rusted solid

onto the cable end, and I could not grab the bolted end enough to

rotate the nut off. I used a lot of WD-40, and two vice grips on

the bolt, but still no rotation. I ended up torching the nut with

my propane torch for about a minute and then after letting it cool,

held the bolt with two vicegrips, and the nut with a non-ratcheting

socket. The heat/shrink cycle of the metal was enough to crack

the rust loose. Wiggling back and forth and more WD-40 finally

got the nut to let loose.

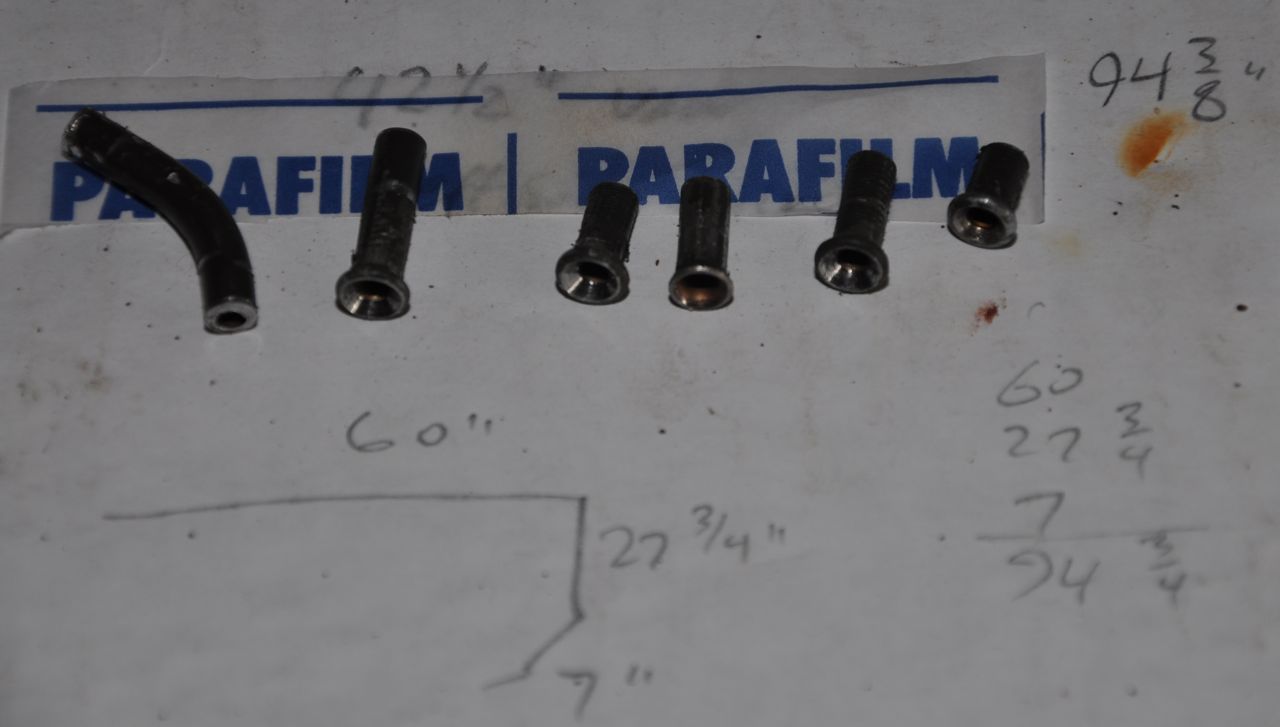

During installation, two modifications were made. The new cables

did not have the

expando-rubber sheaths that prevent water from blowing into the

cables. I slide the old ones off the old cables and installed

them onto the new cables. Also, when installed, the cables came

up about 1" different in length. Either one was too short, or one

was too long. I considered cutting the longer

new cable and crimping on my own end piece. I took a more

reversible path. I hack-sawed off an old crimp

with about 4" pig tail, and used two cable clamps to use the pigtail to

extend the new right side cable.

I still don't know for sure which cable is incorrect. Suggestion

for you: remove your old cables and actually measure them before

cutting them up! After finding the length mismatch, I layed out

my short left side cable and measured 43" between the crimps.

Rock Auto's parts catalogue refers to 44-1/8" length several places, so

I'm thinking my van must have had some shorter version cable installed

years back.

BTW, these brake cables are almost sure to lock up or rust up.

The NEW right side cable is so long, it has tons of friction in

it. I will make sure to use the parking brake every time now,

just to make it practice wiggling in the cable sheath. Dry desert

air also will tend to help. I dribbled some oil into the short

cable, but I'm not sure it will help. I didn't get around to

oiling the long cable before it needed to be installed to make a

departure schedule.

September 2014 - Battery:

After sitting in the garage for

several months, the old battery

(7 years ago) just wouldn't take a charge any more. I purchased a

new one at Walmart. Their cross reference provided a battery type

that was all sold out. The battery tech walked by and said, "Uh..

you have an old Dodge van, right? That's the wrong number anyhow

- it's too tall and skinny. Buy this one. You can get the 3

yr warrantee for $86, or the 5 year warantee battery for

$94." And so I did. Van is back to starting right

away when I turn the key.

Now I need to go work on the pesky air conditioner compressor, which

locked up a while ago. I have a new one purchased but just

haven't had the time to install it yet.

Top of the van paint is peeling due to baking in the hot desert

sun. Looks like it's time to paint the van, too.

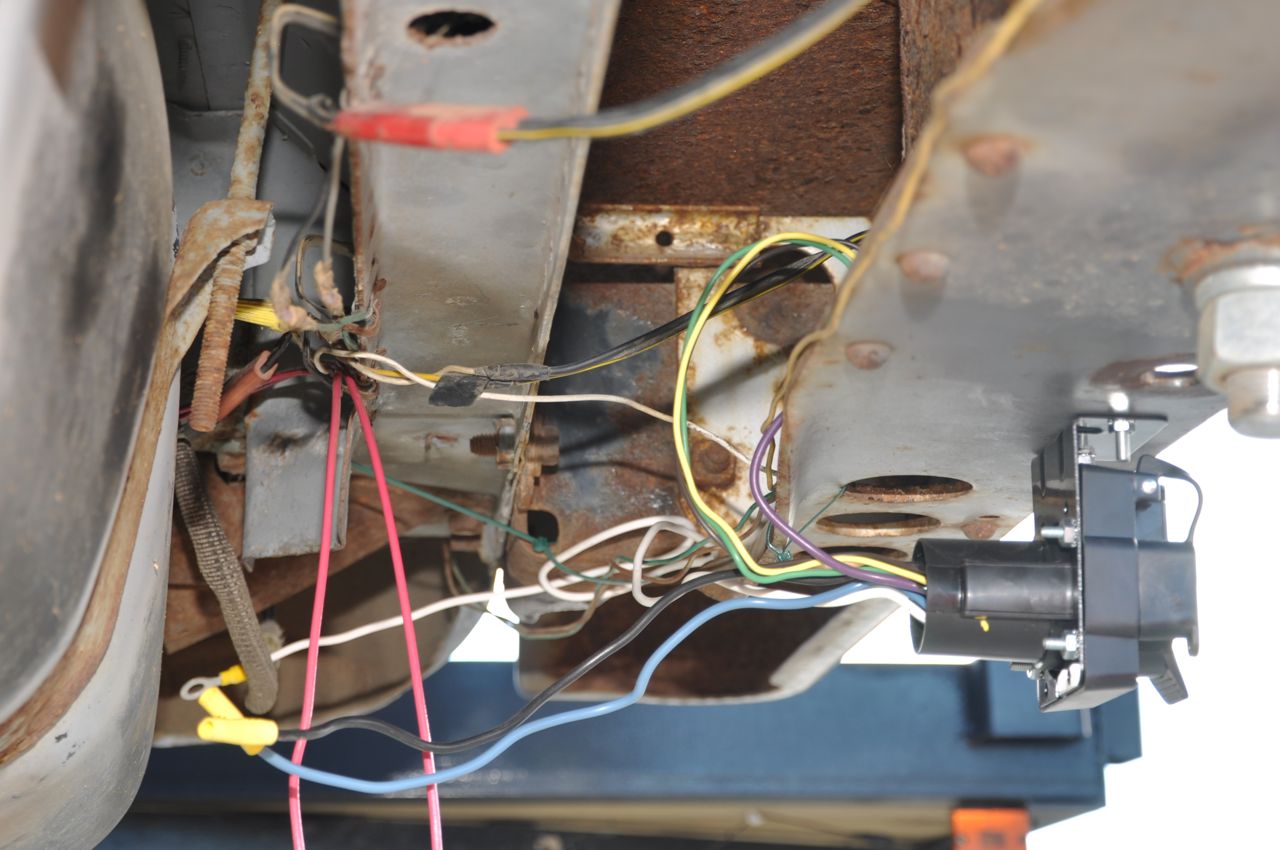

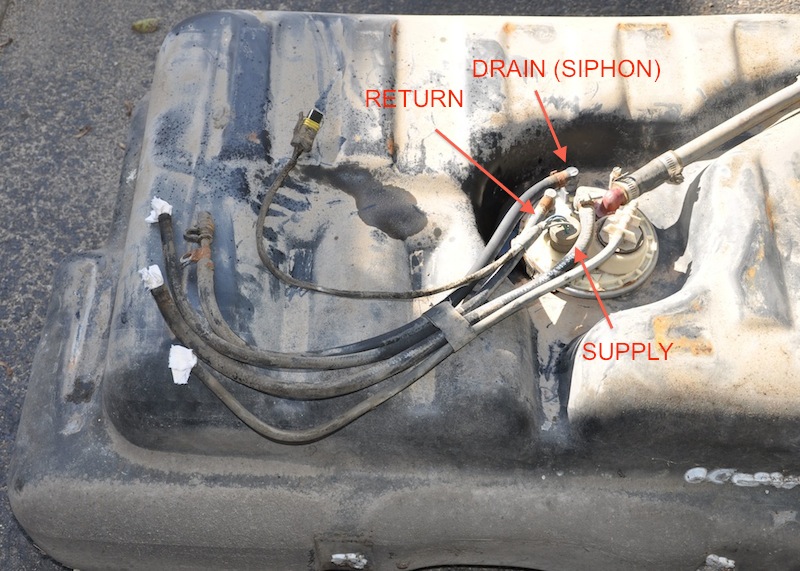

January 2015 - Brake Hydraulic Lines:

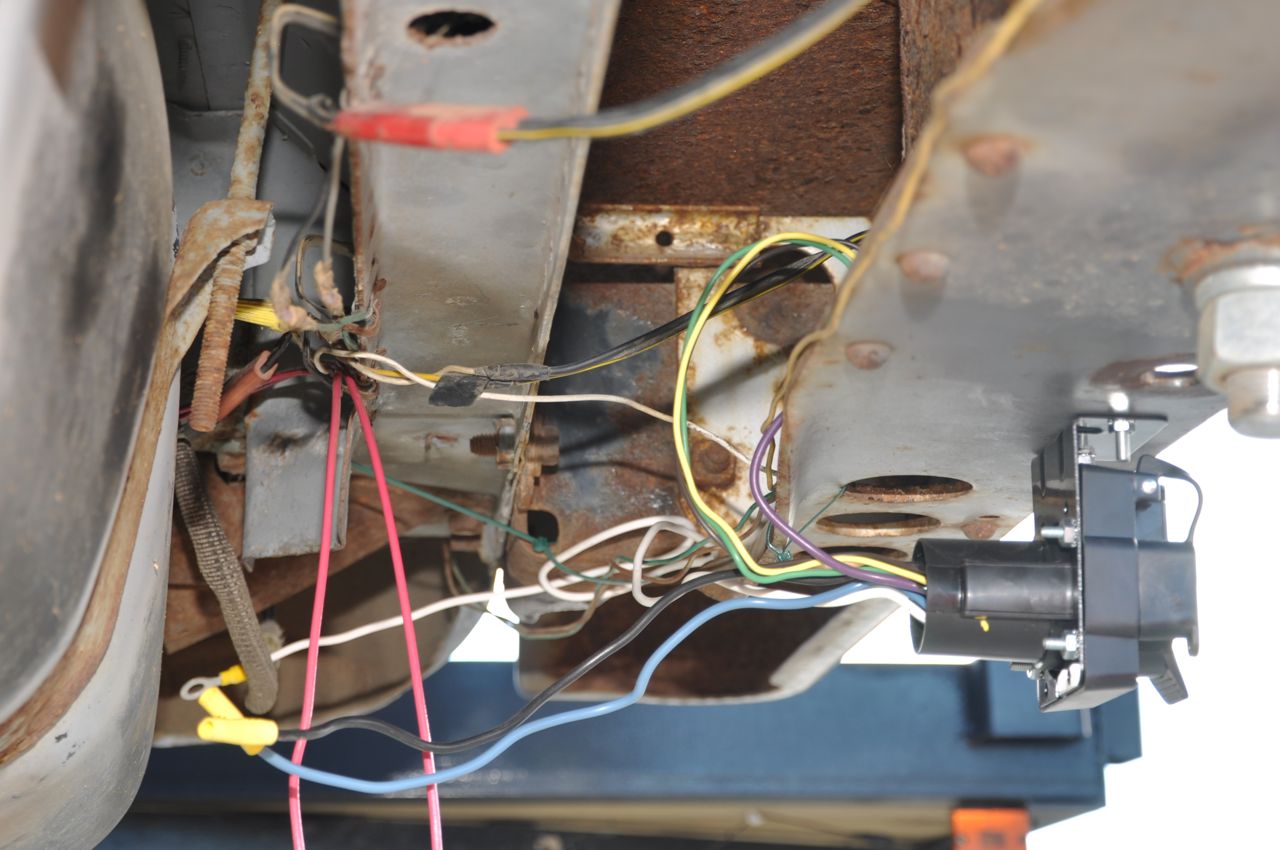

I started crawling around under

the van to route wires for an electronic brake controller. The

brake line going into the rear axle divider looked a bit rusty and the

more I thought about, I had no desire to loose my rear brakes while

pulling a trailer around. I decided to replace the brake line.

If you're doing brake lines, you have to obtain a set of "line

wrenches" - they're like closed box end wrenches with a slot cut in

them to slide over a brake line and then turn the coupling

nut. In this case, Harbor Freight is not the way to go

because theirs have a receeding edge design. It's easier to slip

over a nut, but doesn't grab as much of the nut - and you need all the

surface area grab you can get because these nuts are almost guaranteed

to be rusted badly. This turned into a problem for me.

The front of the brake line connection was along the front left side of

the van. After

unclipping the brake line from

the van body, the front connector nut actually came loose easily and

leaked a

little fluid. I retightened it until I could get the rear coupler

loose.

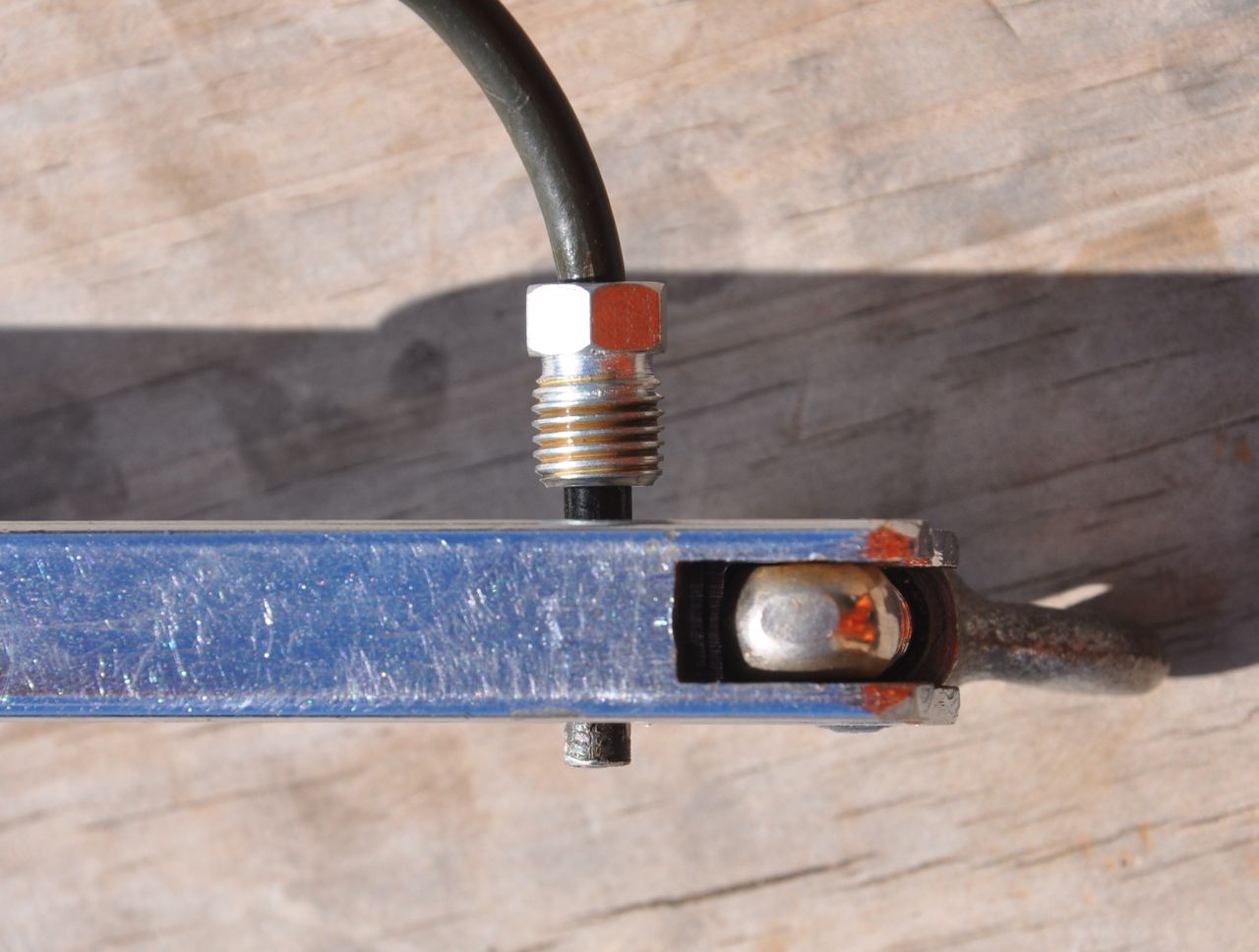

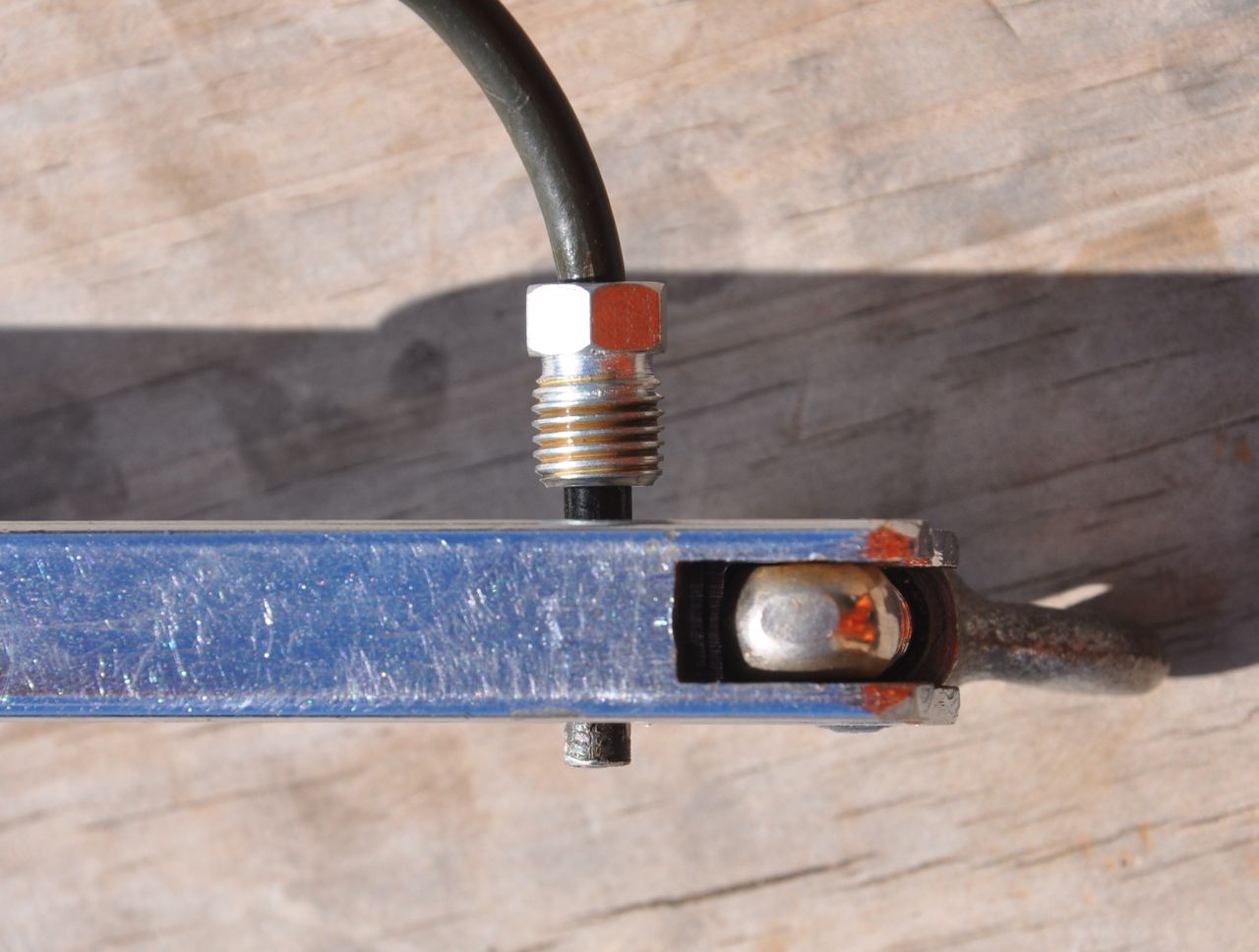

The rear connector was

directly screwed into the flexible hose that

fed the back axle divider. What a rusted nightmare. My

brain was thinking the

nut was like the back of a refridgerator ice maker tubing line, where

the nut screws over the

threads. Not true. For brake line

fittings, the nut slides into

the threaded receptable and pinches the

double-flared end into the coupler. I could not get it loose

until I remounted the hose back into the van frame holder (which had a

hex shaped hole and kept it from rotating). Finally the nut let

loose. I rotated it a few times but the rusty line just in front

of it tore open. I had not loosened the nut, I had torqued the entire

metal brake line until it split.

Turns out moisture gets down between the brake line and the brake line

nut and rusts the nuts up tight. You can expect that the brake

line will twist off or break off or you'll have to cut it

off. However, save the pieces because you'll need them to

get the right length.

You can measure a brake line with twists and turns using a roll of

solder, holding them side by side. However, because I had a

double flare tool, I was able to buy a 25' of bulk 3/16"

brake

line for $21.27. Buying the nuts was a pain. They're only

$2.89 for 5 of them, but do you know that 3/8" and 10 mm are

nearly indistinguishable?! The threads are either 24 tpi or 1/mm,

which is 25.4 tpi - also indistinguishable. Only by looking up

the hose fitting did the

guy at Autozone figure out it must be the SAE size. That was

strange to me because I needed to borrow a friends 9 mm line wrench

when my 3/8" line wrench didn't fit. I think someone during the

last fix accidently put in a metric nut.

Next problem - unless you know otherwise, buy the nuts that have thread

run all the way down to the end. Otherwise, installing the brake

line won't engage enough threads to make a good connection. I

know this because I totally build a new brake line and then had to cut

all the ends off and swap out brake line nuts when the first nut didn't

reach deep enough into the fitting to grab any threads in the coupler.

Use a tubing bender to get the brake line about right. Then use a

plier to wiggle and loose the rusted spring surrounding the old brake

line and install it onto the new brake line so that it does not chafe

against other metal things. I ended up using an abrasive cutoff

wheel to cut the spring into several sections so it would slide on

easier.

Slide the nuts on the ends and create the double-flared ends.

Then fit and test fit over and over again unti the ends nestle into the

couplers straight and snug without the nut. Only then, gently

spin the nut down over the line into the coupler.

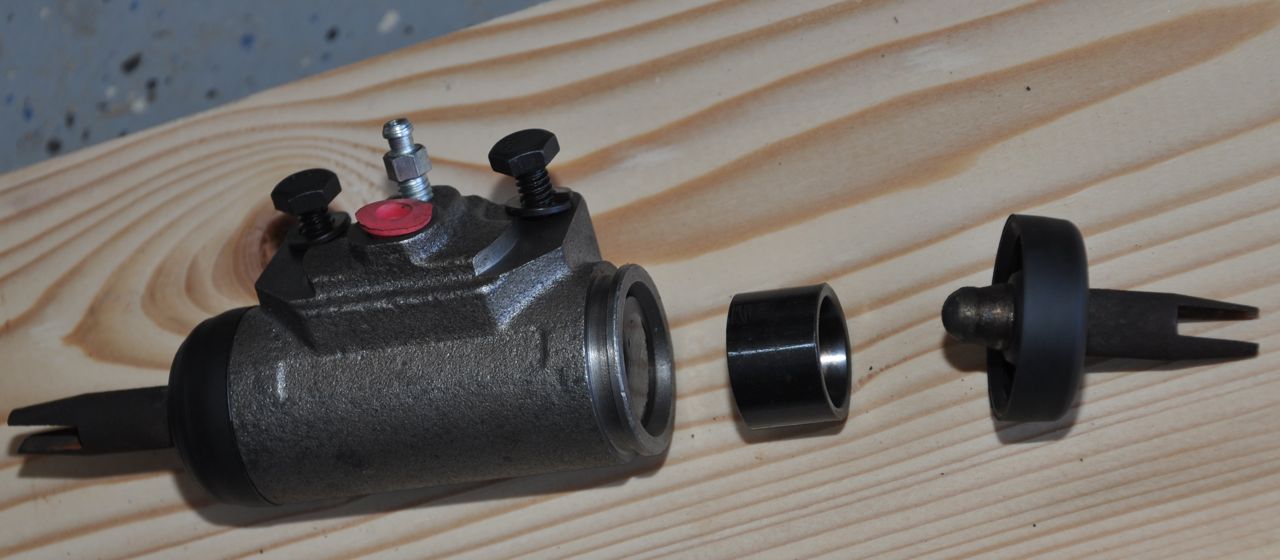

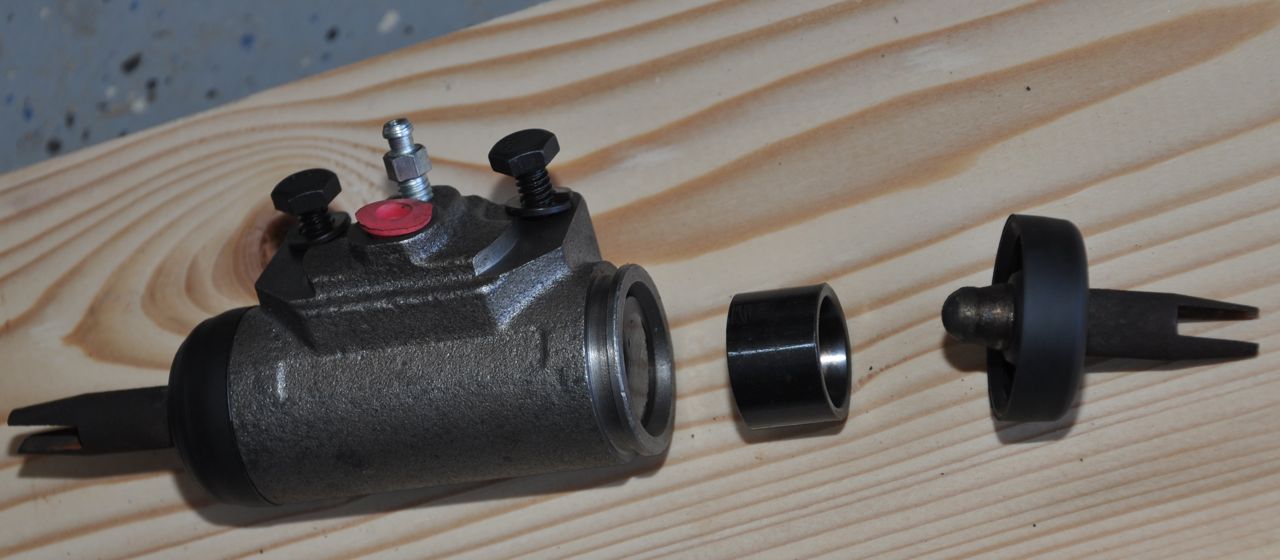

I started bleeding the brakes and the left side worked great.

On the right side, the bleeder valve broke off. There was no

way I could recover the nub, so I had to go buy another wheel cylinder

(the brake hydraulic actuator for drum brakes). Fortunately the

new

one costs only

cost $11. However (!!) this means I had to now pull the brake

line going into the old wheel cylinder. Suffice it to say that it

too was very rusted. I used a torch to heat the nut and it came

loose, but when turning the nut off, it was still rusted to the tubing

and so eventually the tubing torqued off. Now I had to replace a

second brake line.

Turns out the rear axle brake line divider is bolted down to the rear

axle with an incidental axle vent bolt. It backed out easily

after pulling off the connecting breather tube. With the brake

line

divider loose, I was able to grab it with a big crescent wrench and

torque the brake line nut free from the brass fitting. After

another morning of re-making this second brake line from scratch it was

back in

place. It was much shorter, but the angles and bends were much

more compact.

Caution to self: for

some reason, instead of SAE sizes, the new wheel cylinder has 6 mm

threads and requires a 7 mm nut on the hex part. I wish the

manufacturer of this after market piece had not mixed metric size in

because I can so easily see

stripping this some years later by assuming it's the same as the left

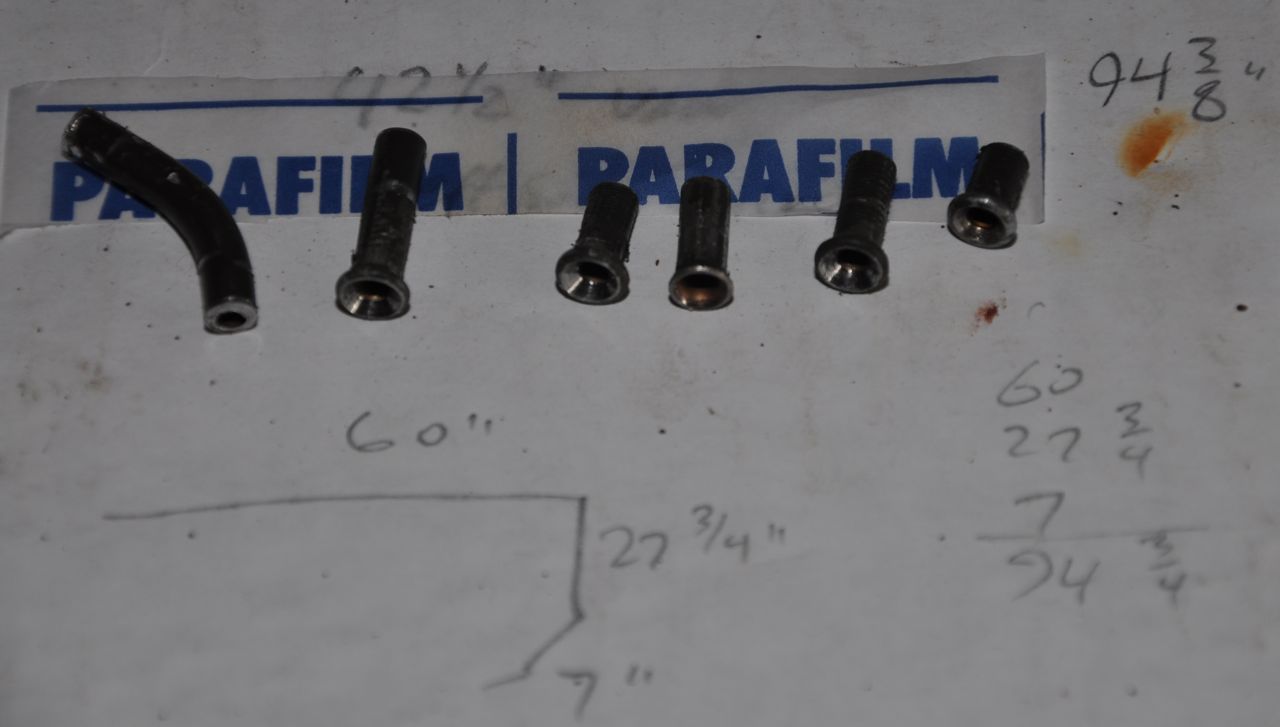

side wheel.

Bled all the brakes. They work good. Checked for leaks and

tightened the ones that were oozing. I wrapped the connections in

Parafilm - it's something I learned about in Chemistry

laboratories. It's like stretchy and sticky wax paper. I

hope the nuts will not rust this time.

For some reason the dashboard brake warning light is still on. I

drained a lot

of brake fluid and I wonder if the sensor saw low brake fluid levels

and somehow got stuck. Or maybe I left some bubbles in the brake

line?

... a week later after driving about 200 miles on the van.

Although the brakes felt firm, I bled the back brakes again and got a

few good sized bubbles. However the brake warning light was still

stuck on. I pulled the front wheels on the van one at a

time. Bleeder valves were stuck firm. I treated them with a

propane torch for about 45 seconds and while they cooled, used a

6-point socket and a small ratchet. They gently came loose.

No problem bleeding them. Afterward, the brake warning light is

off. I think the shuttle or proportione valve up front must have

gotten stuck when I drained so much fluid out the back brake

lines. Bleeding some out the front put the shuttle back into

operation. Yea!

Incidentally, while the engine was running, I pulled the sensor wire

off the font/rear brake proportioner valve down below the master

cylinder. Light stayed off, and that doesn't make sense. I

wish I knew how this

worked.

To see full-size images for brake line

installation, right-click and

open in a new tab.

Original problem. The brake line looked just a little

bit too corroded to take the van on a cross crountry trip.

|

Pulled

the front coupler loose. You can see the clip and a little stone

I used to hold the line out away from the van body. The fluid

source side is wrapped in Parafilm to keep it

from leaking.

|

Work area on the right rear tire.

|

When I was bleeding the back

passenger side brakes, the bleeder valve broke off.

|

I

bought a new drum brake hydraulic actuator ("wheel cylinder") and

pulled the bleed valve from that one. It was much different in

size. Picture shows old wheel cylinder with brake line removed,

showing a shiny brass colored compression fitting seat.

|

In

order to replace the wheel cylinder, I had to disconnect the brake line

- which broke, so now I needed to disconnect the brake line from the

fluid divider mounted to the reare axle. After unscrewing the

axle vent line tub, the brake divider could be lifted up enough to grab

it

|

On

the right is the line nut that did not seat enough threads. Plan

B is on the left, which worked fine. I could have gotten a taller one -

the important part is that the threads run down all the way to the

bottom.

|

Tool

kits to make new brake lines. The anti-chaffing sprinks were wiggled

off the old lines and then cut into pieces to easily slide onto

locations where the clips will grab the new line.

|

Old

brake line at the top (with nuts broken off becuase they were too

rusted to turn). Bottom is the new line. With no flares or

nuts, check the fit and bend/cut as necessary.

|

First step in double flaring a

tube. Clamp the tubing end after sliding springs and nuts on.

|

Second step in making a double flare

is pushing teh 45 degree polished point into the end.

|

New double flare on the end of the

brake line.

|

I made several mistakes with wrong

nuts and wrong lengths and bad flares.

|

This

is the new wheel cylinder about to get bolted into position on the

brake housing. The cylinder cups came new. The rods out

each end were salvaged from the old cylinder.

|

New

line into position where the original problem was first noticed near

the back axle passenger side. Viewed from the wheel well.

|

New long line into position where the

original problem was first noticed near the back axle passenger side.

Viewed from under the van.

|

New short line into position near the

rear axle fluid divider. Connections are again wrapped in Parafilm until I'm

ready to connect them to prevent oozing out lots of brake fluid.

|

Parts photo, so I know how everything

mounts.

|

OriParts photo, so I know how

everything mounts in order to replace the wheel cylinder.

|

Passenger

side rear brake adjustment. I can never remember which way to

move the tooth gear when reaching in with a screwdriver, so this

picture is to help me remember!

|

Driver side rear brake

adjustment. I can never remember which way to move the tooth gear

when

reaching in with a screwdriver, so this picture is to help me remember!

|

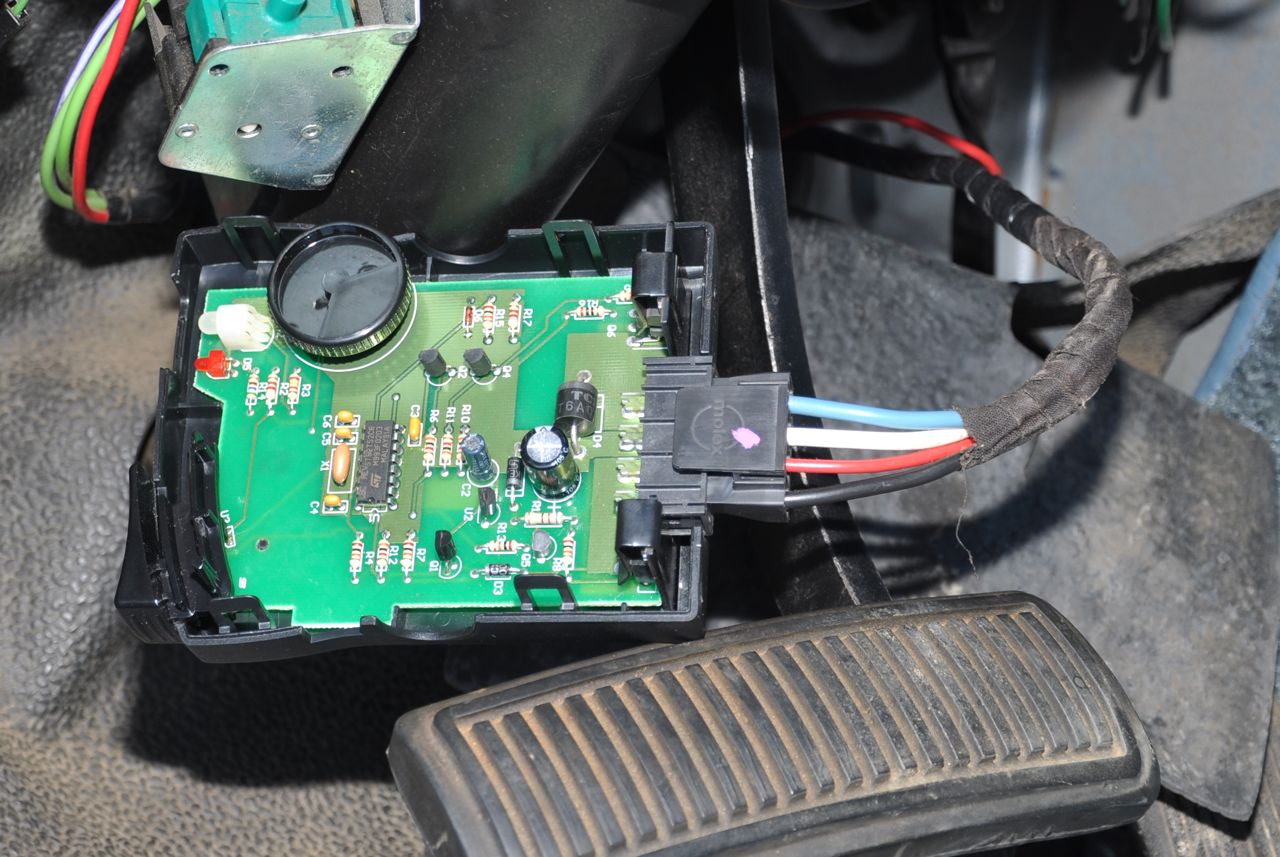

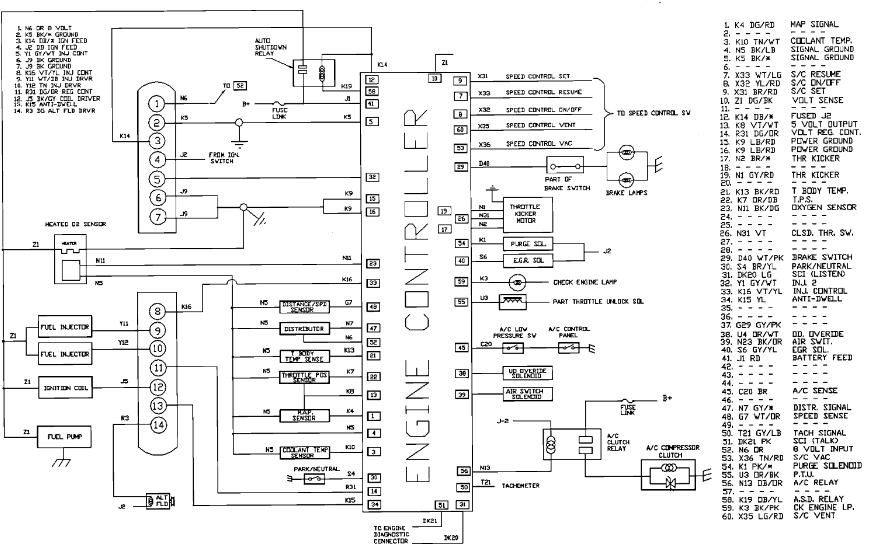

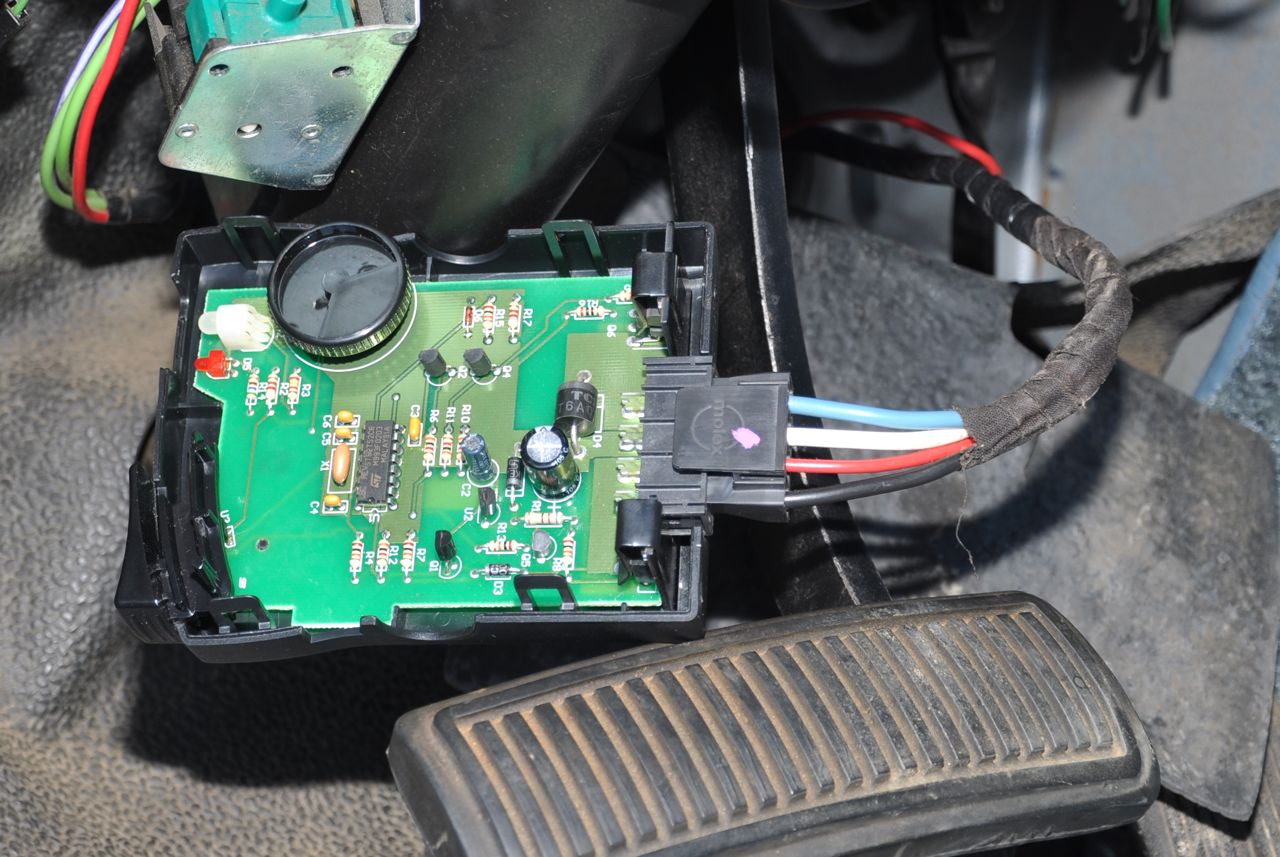

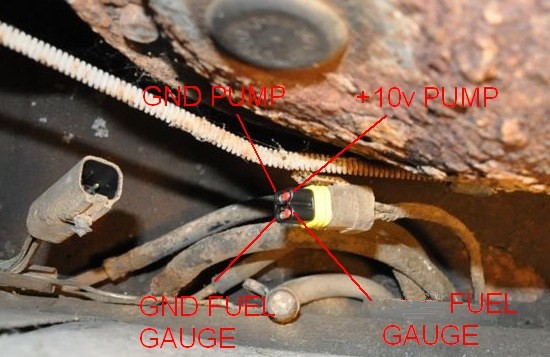

February 2015 - Electronic Trailer

Brake Controller:

Back to the electronic trailer brake controller.

There was lots of tedious work. Of course, a brake wire had to be

run to the back bumper. This comes from the new controller

mounted on the instrument panel of the van. When I used only the

trailer mounted battery separate from the vehicle to actuate the

brakes, the brakes took about 4 amps, so I figure that's about what

would be pulled through this new wire.

I also decided to run a hot 12-volt line fromt the battery to the back

in case I wanted

to run any systems and to keep the brake break-away backup battery (say

that 5 times quickly!) charged.

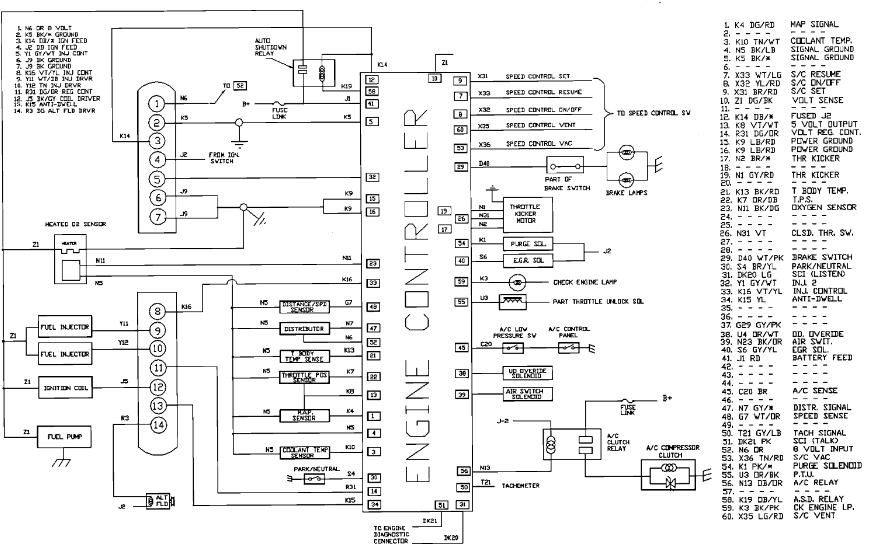

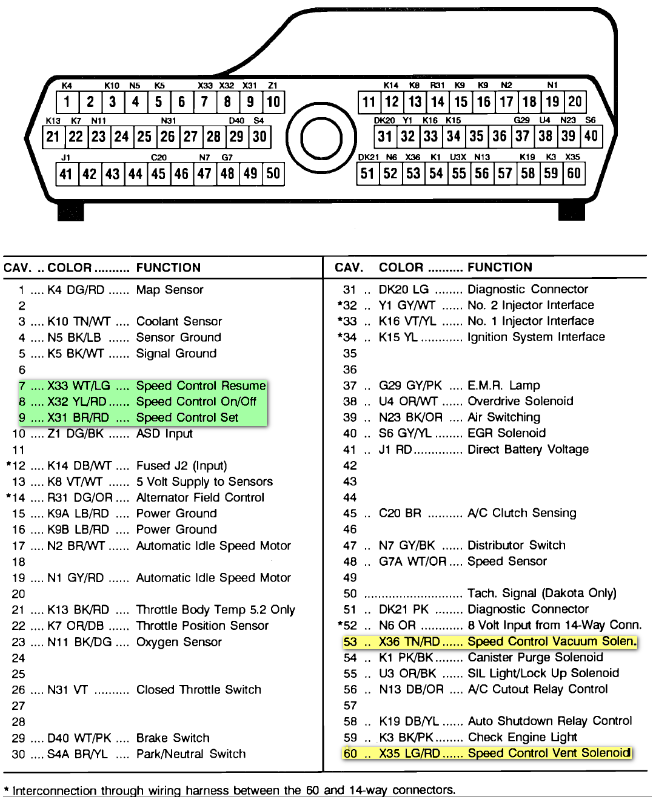

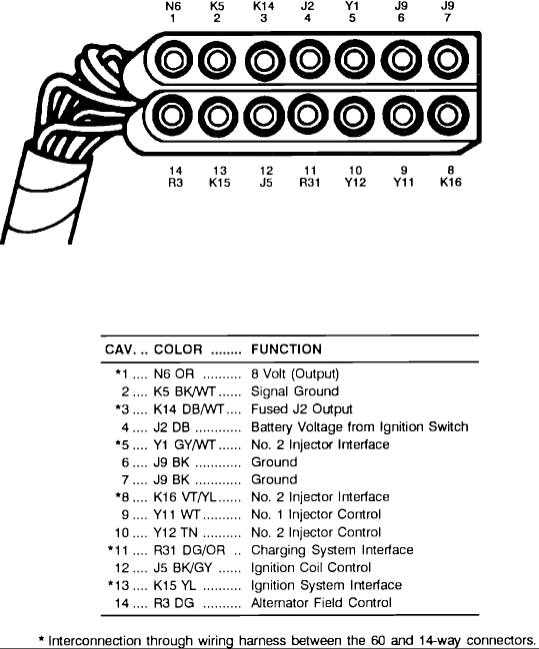

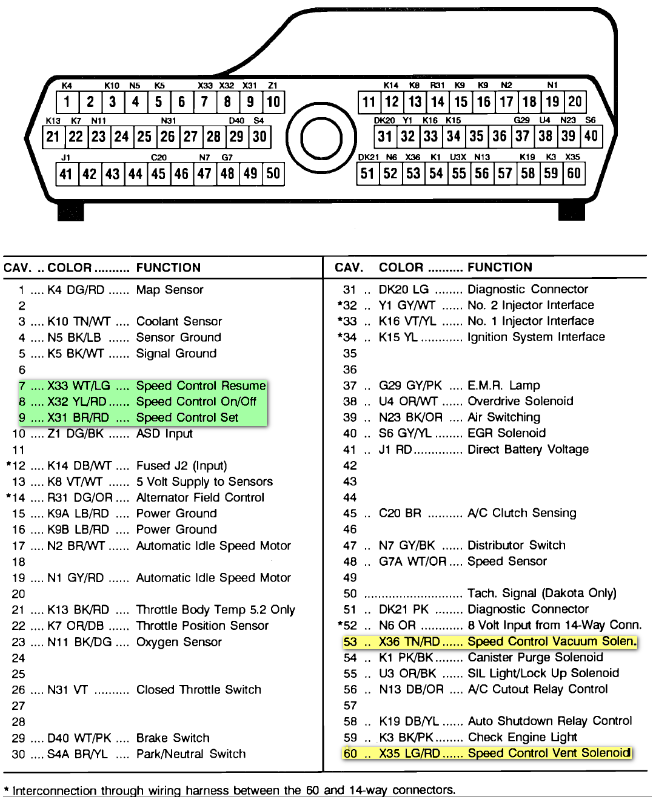

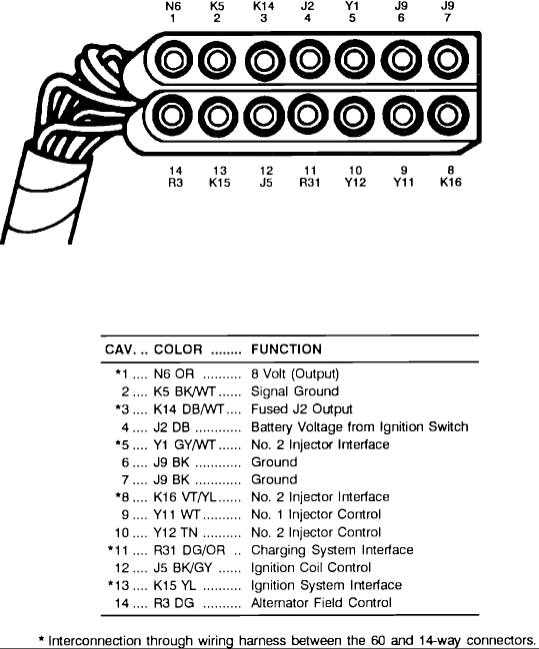

Finding the switched brake line

operated by the brake pedal in the van proved to be a problem for

me. I

initially used the White

w/Pink wire because the Engine Controller schematic above shows it

comes out of the ECU (signal D40, pin 29) and goes to two brake

lamps. It seemed that this is what I wanted because it would be

used

to light up the brake lights and this is what the controller

needed. After connecting, stepping on the brake worked fine

(the brake controller LED stepped up in intensity slowly bringing the

trailer brakes on line). However, when I used the manual

slider switch on the brake controller, the fuse I installed feeding the brake

controller popped.

Finding the switched brake line

operated by the brake pedal in the van proved to be a problem for

me. I

initially used the White

w/Pink wire because the Engine Controller schematic above shows it

comes out of the ECU (signal D40, pin 29) and goes to two brake

lamps. It seemed that this is what I wanted because it would be

used

to light up the brake lights and this is what the controller

needed. After connecting, stepping on the brake worked fine

(the brake controller LED stepped up in intensity slowly bringing the

trailer brakes on line). However, when I used the manual

slider switch on the brake controller, the fuse I installed feeding the brake

controller popped.

I opened the case of the

controller to see what I had fried. Fortunately all looked okay.

So.. out came my voltmeter and I took apart the

switch on the brake pedal and documented what's what. Turns out

the White w/Pink is hot all the time. Hmm.. This doesn't

seem to match the

schematic.

The brake switch is a 3-pole

switch. Two of the poles are NO

(normally open) and one is NC (normally closed). When the button

is pressed, the NO poles operate first and the NC operates

last. That said, the NO and NC descriptions are electrical

descriptions for the switch,

out of circuit. As installed in the van, the switch is normally fully

compressed and when you press the brake pedal fully, it's released to

it's normal status.

The

normal switch normal is reversed

operationally for the brake switch. The NC is usually open and

closes first when when the pedal is pressed. The NO poles then

open.

The

normal switch normal is reversed

operationally for the brake switch. The NC is usually open and

closes first when when the pedal is pressed. The NO poles then

open.

White - NC - Pink

Black - NO - White w/Pink stripe

Blue - NO - Yellow w/Red stripe

The Pink wire carries battery power to the switch even when the car is

off and the key is out of the ignition. For me, it was 12.1 volts

with the engine off and 13.5 volts with the engine running (alternator

was raising the voltage). When the brake pedal was ~not~ stepped

on, this pink wire fed voltage to nothing. When I stepped

on the

brake pedal, the NC usually open connection was closed and the white

wire received the 12 volt power. I connected the brake controller

to the white wire and now it works fine.

I purchased a bumper 7-wire trailer connector, and added to the

rat-nest of wires tucked into my rear bumper!

Pending:

Replace the A/C compressor and other things that came with the kit

remains an open item. Commerical estimate was $1200 even with the

parts provided and that is unreasonable considering I did it for a Ford

Aerostar one Saturday morning using a compressor salvaged from the junk

yard.

Also, the top and front panels of the an need a paint job or they are

going to start showing deep rust spots instead of blemishes. $600

estimate, but I'm not sure it's worth the super nice job the car

restorer is capable of. I'll probably sand blast, air disk sand,

spray prime and mostly match the color with whatever paint I can get.

April 2015 - Frame Hitch:

After driving the 18' car

hauling trailer around for a few days, it became clear that using the

ball on

the step bumper made the metal plate flex. Several people

reminded that flexing metal over and over makes it fatigue and

fail. Building up the bumper would have taken a lot welding

skills I don't have. Instead, I purchased a frame mounted hitch,

which I had avoided doing because all the manufactureres say the hitch

can't be

used with the step bumper. After comparing several brands, I

settled on a Curt hitch,

http://www.etrailer.com/p-C13041.html

I was fully prepared to travel

across the country with no bumper on the van because the trailer would

be connected the entire time. However, things worked out better

than

expected. The step bumper is bolted to the vehicle with 4

horizontal bolts on the left and 4 horizontal bolts on the right

side. The bumper has to be installed after the hitch, which uses

only 2 bolts on each side. By inserting 3-4 spacers (washers)

between the

van and the bumper on the bolts the new hitch hangar did not use, the bumper could be

mounted in the same place, only about 1/8" aft. I also had to

grind away about a 1" x 1/8" strip

of metal edge from the body frame as explained in the hitch

installation instructions, but this is unrelated to using the

bumper. No drilling was required, but I did

use a high pressure air hose and blow out a lot of dirt and stones from

the body frame before inserting the bolts.

I don't see any reason spacing the step bumper backwards about 1/8"

with

spacers caused any problems, so after removing the bumper and

installing the hitch, I put the bumper back on the van. To

be clear, the Curt C13041 hitch DOES

work with the factory step bumper if you space the bumper backwards a

fraction of an inch.

To see full-size images of frame hitch

installation, right-click and

open in a new tab.

The hitch was heavy, so I bolted up

one side with a hangar single bolt, and then swung the other side

up into position.

|

This shows the metal flange that

needed to be cut away so the hitch would ride up high against the frame

mount holes.

|

Size of the piece removed. This

was done on the left and the right side.

|

How

do you get a bolt through the washer and then through the frame from

the inside of the frame? Screw on a 2' section of music wire and

fish that through the hole first.

|

This

shows the music wire pulled down through the hole; the bolt follows and

a little wiggling makes it seat properly into the nut.

|

This shows two left-side bolts

installed with nuts and the third one pulling through.

|

After

the bolts are pulled through, ready to receive nuts. Screw the

nuts on carefully or you'll push the bolts back up into the frame.

|

This

shows the new washers installed to equal the thickness of the hitch

hangars, allowing the step bumper to be bolted back into place.

|

I was prepared to notch the step

bumper to clear the ball, but it has just

enough room to allow the trailer tongue to drop down over it.

|

Bonus

picture! (Not about hitch installation). The tongue weight

was too heavy for my bathroom scale, so I made a little lever arm,

measured the distance and calculated the weight of the tongue.

|

October 2015:

And the trailer weight winning

trip so far is when we used the van to move about 1 cord of

firewood. The trailer with the homemade sides installed is 18' x

6.8' x 2', or 245 cubic feet. A cord of neatly split and stacked

wood is 128 cubic feet - about half the trailer volume. I figure

the trailer would have been about half full if the wood had been

split and neatly stacked on the trailer. Firewood weight

estimates say a cord would weight about 3800 lbs.

The Class III hitch worked fine. Without a scale for the

tongue weight, I notice how high the hitch is before loading and load

the trailer so it drops down about "400 pounds worth". There was a spring left

in the suspension and handling was fine. Dual

axle electric brakes worked great when I adjusted them to gently feel

the braking when only the trailer brakes are applied.

4820 lb van + 1900 lb trailer + 3800 lb wood + 340 people => 10,860

lbs.

This was enough wood for about 1/3 of the annual heating needs of the

house. With fuel oil it's about $1,875 / yr, so this trailer load

was about $625 worth of heating after splitting it. Commerical

firewood was $150-$185 per cord, so that's the replacement cost value

of a 1 cord trailer load.

2016:

So far, the tow hitch has done well and this has become our work horse

vehicle. Two heavier trips were:

4820 lb van + 1900 lb trailer + 1760 lb cargo and Cessna 140 airplane +

170 people = 8,650 lbs.

4820 lb van + 1900 lb trailer + 2600 lb tractor + 340 people = 9,660

lbs.

The

van has moved about 8 trailer loads of wood - at least 10 tons.

Everything is working fine. The 3/4-ton B250 frame is doing as

well as a new Chevy 1500, Ford F-150, Dodge 1500. In

March, the Ram Van Wagon and trailer was used to bring home a 2600

lb Massey

Ferguson GC2310 front loader and backhoe. You can read my

other webpage about the GC2310 repairs.

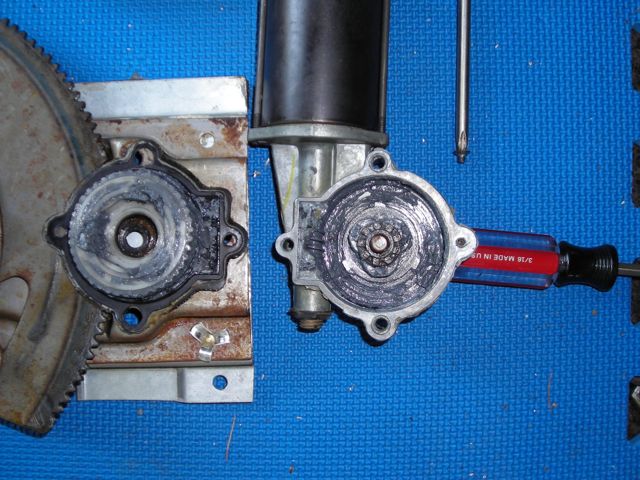

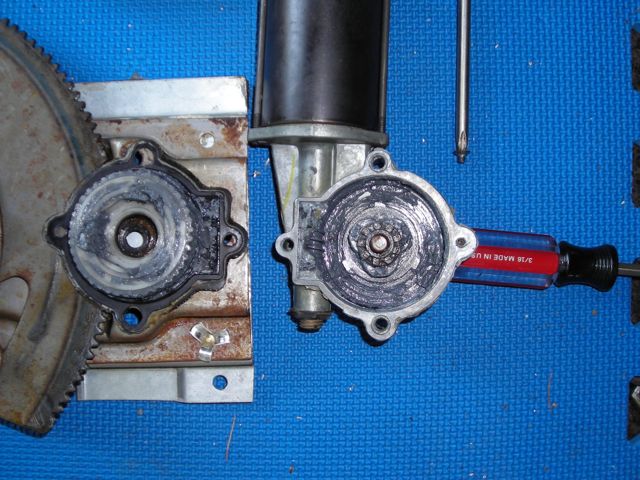

September 2017 - Window Regulator

The driver side window quit going up

or down. I can hear the motor spinning, but no window action!

To fix the window, removing the door asthetics was pretty easy down to

bare metal. The only difficult situation was the powerful spring

that gives some up-force to the window - which makes it more balanced

for the motor to lift up or pull down. Because the internal motor gears

were broken, nothing held back the powerful coil spring trying to

rotate the arm. Unlike many scissor lift

regulators, the 1989 B250 has only one arm that reaches to the window

rail and it pivots against the motor assembly, which is held to

the door with four rivets.

After taping the window up into position so it cannot fall into the

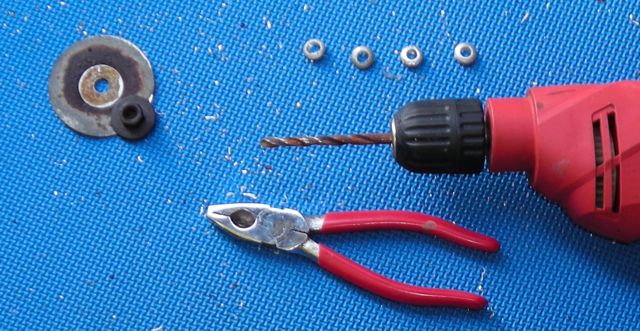

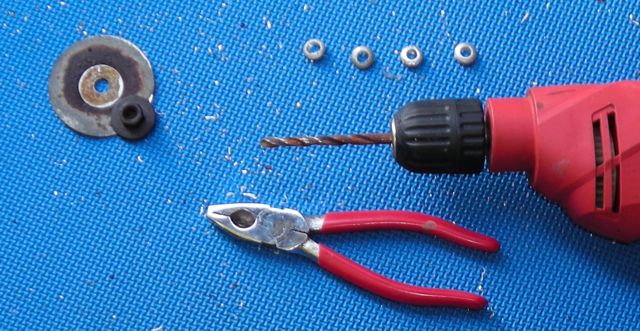

door, I punched out the middles of the four rivets using about a 3/16

punch. To

remove the motor unit and window lift arm, first the steel core of the

rivets were punched out. The second picture shows the little

rivet heads that fell into the door with the punch and hammer.

After the cores were removed, the

rest of the rivets were drilled out. I

used a 15/64" drill bit. Use a crisp plier to grab the head of

the rivet as you drill so it will not spin. Use a new or sharp

drill bit so it does not snag or grab on the rivet. When you

break through, tilt the drill a little up, down, right, left until you

cut away enough rivet for the head to be pulled off.

The big washer and nut in

the third picture were removed from the outside

bottom of the door. They secure the bottom of the forward window

track

and if they are removed, the track can be wiggled around to make the

motor fit out easier. Be sure to install the eccentric bolt post

back

in the same angle position when re-assembling so the window track is

set correctly to not warp or twist the glass window when it comes down.

If your drive motor gear

is broken, the motor cannot hold the position of the lift arm, so the

third rivet you drill will be under tension because as soon as its

free, the whole motor assembly will rotate on the last rivet and

attempt to "clam shell" close against the lifter arm - that's the

spring doing its job without any gears to hold it from moving.

Turns out at the very end of the toothed

gear you can see, there is no tooth notch in the last position, so the

clam shell closing action gets stuck on the last tooth of the

gear. Confirm this is true (no pressure on the clam shell

closing), then drill out the last rivet and the motor assembly will

drop down into the door, which allows the window lift roller to come

off the edge of its track.

Manuever the entire assembly out of

the door.

Before unbolting the

motor from the arm assembly, you need to remove the gear tension from

the motor drive

shaft. Press the arm and rotate it until you can stick a bolt

through the hole and lodge it against the motor frame (see in the

picture above). Then you

can safely unbolt the motor.

After removing the motor,

the fourth bolt position is secured by a screw only accessible after

you remove the motor from the frame. A phillips screwdriver

easily removed the screw. Gently peeling the rubber/fiber seal

off the face of the gears reveals the gears on the inside which

disintegrated like every body else's. I ordered new gears..

Turns out the near gears,

purchased from Rock Auto were 8 pieces: a plastic outer gear, and inner

metal gear, 3 bumpers, an o-ring for the shaft, a gasket cover, and a

plastic bag of grease. The bumper parts that had been shredded

look and feel exactly like hardened wood glue in the stem of a bottle

when I forget to put the top on! They're little 0.5" diameter

cylinders bumpers, 0.45" tall. I would try making my own next

time.

The old gear sealing gasket had 3 positions secured by the mount bolts

and the last position was secured by a flat head screw. Turns out

the new piece was incorrectly made with a hole too big so that the flat

head screw secures nothing when installed (it just sits in the cover

hole). I considered using the old gasket but maybe it was a

little torn in the middle and may have had a slightly different shape

rubbing against the gear. The screw has very few threads and small

clearance against the big gear arm, so I could not use a metal washer

to hold the gasket down. Instead, I used a nylon washer and I

hope it will stay in position. If the screw backs out, it will

jam against the big gear arm and make scrappie noises or just twist

sideways and bind up the whole mechanism. I wish the replacement gasket part part

had been designed right.

When you install the new gears and bumpers, the clamshell close

pressure will be gone; the motor holds the gear into

position. However, you should connect up the motor connector and

run the control arm almost to the end of the gear because the entire

assembly fits in the door better that way.

I put the roller track wheel into the window track and connected one of

the four bolts (using bolts instead of original rivets). Then I

carefully tapped the window "up" and "down" which, instead of moving

the taped-up window, made the motor assembly change position and

perfectly align the other 3 bolts.

I jostled the front window track around until the window tracked

without a lot of pressure or torque, and then tightened down the big

washer and nut on the bottom exterior side of the door.

The only problem is that the aft window felt guide inside the door is

torn. When the window opens (descends), it doesn't go intot the

track. Instead it pushes in between the metal track and the

rubber felt liner. I need to get a new window rubber/felt.

So.. uh... 9 months later I finally got new window rubber/felt runners

and had the time to install them. I purchased the kit made by

Fairchild Industries, part #KD1004, from Rock Auto for $35.78 including

shipping. Two for the left window and two for the right window